Contact Details

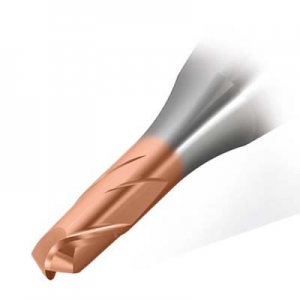

Walter USA, Waukesha, Wis., recently introduced its new Advance product line, which the company claims increases tool life up to 50 percent.

The MC251 Advance solid carbide milling cutters from Walter's Prototyp brand is said to be the ideal geometry for machining stainless materials from material group ISO M and for secondary applications in ISO S materials, according to the company. The new MC251 tool family is designed to operate most efficiently on machines having only an external coolant supply.

The MC251 product family comprises a tough carbide substrate (WK40RC), which has been specifically designed to provide a high level of machining reliability. The tool's coating, made from a combination of titanium aluminium nitrate (TiAlN) and aluminium titanium (AlTi), is designed to increase tool's service life as well as provide anti adhesion properties.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS