Contact Details

MicroPlus, ANCA's new high accuracy workholding and tool support system, significantly reduces tool runout during grinding, enabling the production of higher precision tools with no additional cycle time.

The two-component system consistently limits radial and axial runout to less than 3µm (0.0001" for tools 50mm (2") from the face of the collet. Typical tool grinder runout is about 0.0002" Suitable for both manual and automated tool loading, it is ideal for the production grinding of 3 to 13mm diameter tools. A conveniently packaged system, collets are easily changed over and the machine work envelope is unrestricted.

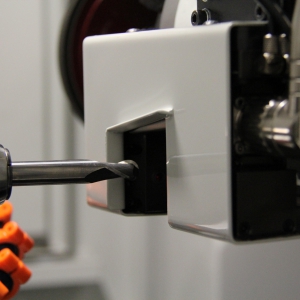

The ANCA MicroPlus system consists of two separate assemblies: the Flexi-Chuck assembly for workholding and the Overhead Top Clamp Assembly (OTC) for tool guidance. Together, these devices provide a system that delivers consistently lower runout than any existing system.

The Flexi-Chuck clamps and rotates the tool to be ground, preventing any negative influences from affecting the guidance provided by the OTC, such as collet inaccuracy, inconsistent collet clamping and any misalignment caused by loading tools.

The clamping force is generated by disc spring stacks within the Flexi-Chuck assembly. This provides sufficient force to clamp tools effectively. Flexi-Chuck does not use the conventional draw bar design and so is not affected by a drawbar system's potential negative influence on tool runout.

The Flexi-Chuck allows the tool and the internal components that lead to it to move independently of each other, absorbing any potential misalignment. With MicroPlus, tool guidance is achieved by the Overhead Top Clamp assembly and the collet float of the Flexi-Chuck. This allows the Overhead Top Clamp to guide the tool into a accurate workholding position without the Flexi-Chuck influencing tool alignment accuracy. The innovative new workholding part of the MicroPlus uses the flat-nose Schaublin W20 range of collets. Collet sizes range from 1mm to 13mm (1⁄32" to ½").

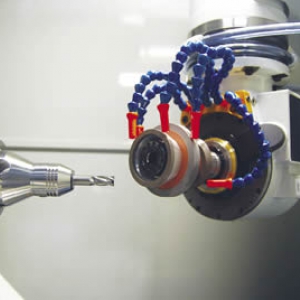

Providing runout and alignment accuracy for the tool, the Overhead Top Clamp consists of a rigid V block that supports the tool to assure axial and angular alignment. The OTC retains the tool in the precision V block with an overhead clamp. The clamp is a rigid metal finger with an acetal pad to prevent damage to the tool shank during grinding. The OTC is mounted on a rigid steady bed, and the tool is clamped and unclamped by a pneumatic actuator. The operator can adjust pneumatic clamping pressure of the finger to suit different tool types and diameters.

Automated set-up assistance for MicroPlus is provided in ANCA's ToolRoom software. This helps the operator to set the centerlines of the Overhead Top Clamp assembly with the Flexi-Chuck, in both vertical and horizontal planes.

The MicroPlus is available for the MX7, GX7 and RX7 tool grinders as an option and can be retrofit to these machines.

Related Glossary Terms

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- work envelope

work envelope

Cube, sphere, cylinder or other physical space within which the cutting tool is capable of reaching.

PRODUCTS

PRODUCTS