Contact Details

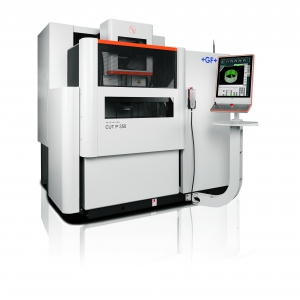

With its new MIKRON HEM 800 three-axis vertical machining center, GF AgieCharmilles says it brings an excellent price/performance ratio to the high-precision production of medium to large-sized parts for several different industries, from aerospace to electronics to mold and die.

As one of five machines in the company's latest High Efficiency Machining Series, the MIKRON HEM 800 cost effectively places GF AgieCharmilles' best technologies in a modern, reliable and ergonomic machine that brings irreproachable operation to a wide variety of milling applications.

The MIKRON HEM 800 has a 41.34" x 22.05" work table with a maximum payload of 1,760 lbs. Maximum X-Y travels measure 33.46" and 20.87", respectively, with a Z-axis that provides 23.62" of clearance between the table surface and spindle nose. Rapid traverse rate for the X, Y and Z axes is 1,181 ipm.

Furthermore, the MIKRON HEM 800's oversized table offers enough surface area to safely clamp machined workpieces. The table's T-slots, with 3.94" spacing between each one, permit flexible part fastening and quick alignment to the machine movements.

The machine's highly dynamic 12.75-hp, 14,000-rpm, CAT 40 spindle generates 31 ft-lbs of torque and enables high-powered milling and drilling operations in the Z-axis. The generously sized spindle motor provides uninterrupted production both with high torque at low speeds and high power at high speeds. Overall, the spindle design permits best balance and vibration-free milling performance at full speed. During operations, a closed internal coolant circuit stabilizes and controls temperature drifts of the machine's spindle head.

The MIKRON HEM 800's side-mounted automatic tool changer has a capacity for 30 tools and allows for faster uninterrupted production. GF AgieCharmilles kept the tool changer separate from the working area to protect the tools from chip contamination. And because high-performance machining yields large amounts of chips, the company designed the MIKRON HEM 800 with sharply inclined sidewalls combined with flushing systems that direct chips straight to the evacuation channels. Chip conveyors then efficiently transport the chips out of the work area.

Two adjustable high-flow coolant nozzles and air blow-off nozzles ensure good lubrication of the cutting edge, prevent premature tool wear and enhance machining accuracy, as well as facilitate efficient chip evacuation.

The new Heidenhain TNC 620 digital control system on the MIKRON HEM 800 provides quick and reliable machining with high contour fidelity and is recognized for offering best performances and programming comfort. The user-friendly interface supports safer and faster programming and faster data transfer from programming stations. The control also features application-oriented setup functions that help reduce nonproductive time.

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- payload ( workload)

payload ( workload)

Maximum load that the robot can handle safely.

- rapid traverse

rapid traverse

Movement on a CNC mill or lathe that is from point to point at full speed but, usually, without linear interpolation.

PRODUCTS

PRODUCTS