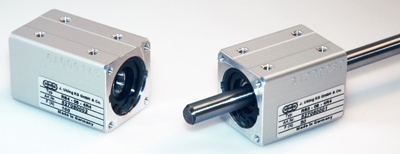

Model RS Drive Nut

Model RS Drive Nut

The Amacoil-Uhing Model RS drive nut provides smooth backlash-free linear motion in machine design.

The Amacoil-Uhing Model RS drive nut provides smooth backlash-free linear motion in machine design. Unlike a screw, the RS drive nut runs on a smooth shaft without threads. This eliminates the potential for clogged threads and jamming. If debris does become lodged in the drive nut's travel path, the drive simply slips until the operator can remove the obstruction. Slipping, as opposed to the churning and grinding associated with screw-based systems, prevents damage to the nut and other components in the linear motion system. Additionally, with less downtime required to clean out threads and make repairs, more consistent production rates are achievable with the RS drive.

The RS linear drive operates on the rolling ring linear motion principle. The inner race of each rolling ring bearing inside the nut is specially machined. Each bearing is installed under pressure and contacts the shaft at a single point only. When the shaft is rotated, the rotary motion input is immediately converted into linear output as a result of the friction created. The point contact between the rolling ring bearing and the shaft assures there is no play or backlash during movement of the drive nut. This is true even during reversal.

As components in a variety of indexing and reciprocating linear motion systems, Amacoil-Uhing RS drive nuts have a wide range of application in material handling machines, winding equipment, test and measurement devices, parts transfer systems, packaging machines and other production, converting and finishing equipment.

Available in 10 sizes to meet varying payload and linear speed requirements, the RS drive nut is suitable for vertical or horizontal travel. Each of the ten sizes is available in five different linear pitch settings. Shaft rotational speeds may be up to 10,000 rpm, depending on the size of the drive. Linear travel speed ranges from 0.5 ft/sec up to 4.0 ft/sec, again depending on the size of the drive and also on the weight of the payload. RS drive nuts offer axial thrust from 22 to 449 pounds and the only maintenance required is periodic lubrication of the shaft with grease.