Contact Details

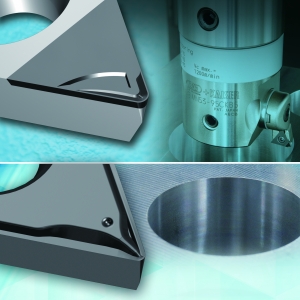

BIG Kaiser Precision Tooling Inc. introduces a new small-diameter indexable rough boring solution for a range not previously available. The new MW boring head permits small-hole rough boring in a diameter range of 16mm-21mm (630"-.827") and is ideal for semi-finish boring operations of workpieces with die cast holes.

Unlike other boring tools from BIG Kaiser, the new MW does not feature the modular KAISER KA/KAB connection. Built with a 20mm-dia. straight shank, the product performs best when paired with a milling chuck at fixed bore depths up to 4xd.

Efficient chip evacuation was a major consideration in the design of this tool. A spiral groove carved in to the body facilitates clean and quick chip removal with the help of coolant holes near the end of the groove. However, for blind-hole situations, an additional center-through coolant option was added to aid in chip evacuation for this tricky scenario. Simple stop screws makes choosing coolant preferences fast and easy.

The two opposing die-steel insert holders feature a precision serrated mounting system, providing a secure and rigid connection similar to the KAISER 319 SW series. The insert holders are conveniently marked with a scale for coarse setting, and the radial adjustment screw allows for fine-tuning thanks to its .008" pitch. Coated inserts are available for common materials like steels (including stainless), ferrous materials such as ductile and cast iron, as well as non-ferrous materials like aluminum.

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring head

boring head

Single- or multiple-point precision tool used to bring an existing hole within dimensional tolerance. The head attaches to a standard toolholder and a mechanism permits fine adjustments to be made to the head within a diameter range.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS