NUM announces CNC solution for gear production machines

NUM announces CNC solution for gear production machines

NUM has announced a high performance CNC solution for gear production machines that fully automates threaded wheel grinding.

NUM has announced a high performance CNC solution for gear production machines that fully automates threaded wheel grinding. Incorporating unique high speed gear alignment technology that is believed to be an order of magnitude faster than comparable control schemes, the new CNC system dramatically reduces grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine threading-in times to accelerate throughput significantly. The comprehensive new solution is ideal for machine tool manufacturers seeking to improve the performance of their gear production machines, or to help companies expand their gear manufacturing range with threaded wheel grinders.

Based on NUM's new-generation Flexium+ CNC platform, the threaded wheel grinding solution joins the company's NUMgear suite of gear production software. Originally developed for gear hobbing applications, the capability of NUMgear has been continually extended and now includes solutions for a broad range of gear manufacturing processes, including shaping, grinding and honing, and is used by many of the world's foremost manufacturers of gear production machines.

NUM developed the latest addition to its NUMgear portfolio while helping an Asian gear manufacturing machine company to improve the performance of a prototype threaded wheel grinder. To improve grinding speed compared with current levels, NUM decided it needed to develop custom technology software. The principal aims were to reduce the time overhead of learning the teeth positions of the hardened gear prior to grinding, and improve the accuracy of the gear grinding process.

NUM's new product offers a comprehensive CNC solution for gear manufacturing machines. At the heart of the system is a high performance electronic gearbox that allows all master axes, such as the grinding, X, Y and Z axes, and the spindle (C axis) to be fully synchronized. As part of the development work on the new threaded wheel grinder, NUM has added a major new capability to the gearbox, which is now able to predict the acceleration of axes as well as their speed, in order to minimize synchronization time. Together with the Fast Gear Alignment, it forms part of the new NUMgear threaded wheel grinding application.

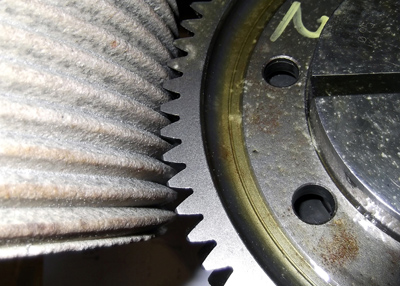

During gear production, "threading-in," the process of bringing the grinding wheel into contact with the gear blank, involves continuously adjusting the position of the grinding wheel relative to the work piece. A similar process is employed when bringing the machine's dressing wheel into contact with the grinding wheel. Using acoustic emission sensors to learn the sound signatures of a master gear and then using them to control positioning during production runs is a common technique for automating processes like this. However, the speed and accuracy of NUM's newly-developed Fast Gear Alignment Function eliminates the need for this entirely. As an example, aligning the grinding wheel with a 180mm diameter gear with 71 helical teeth takes just 0.5 of a second, without any need to acquire acoustic signatures or make manual adjustments.

A second aim of NUM's development required that the gear grinder CNC control should generate gears as accurately as possible. The latest machine from NUM's Asian customer produced gears with a tooth profile quality of DIN class 7. During the development process, NUM found that the diamond plated dressing wheel did not come up to specification. To overcome this problem without incurring major tooling costs, NUM decided to support their customer by helping to modify the technology programs. The positive results of this action far exceeded expectations, and NUM's solution can help a machine to consistently grind gear teeth profiles to within 3.5µm, comfortably achieving DIN class 3, an improvement of four class levels.

The latest gear grinding development is an example of one of the major principles underpinning NUM's business philosophy: a willingness to customize its CNC technology for machine makers. NUM supports this with a decentralized R&D structure which locates engineering staff around the world to allow it to work closely with machine builders. In this case, the new gear grinding solution was jointly developed by NUM's HQ in Switzerland and the company's technology centre in Chanzhou, China, which is close to many major gear manufacturing machine builders and is currently undergoing major expansion.