Paradur HT HSS-E Blind-Hole Tap

Paradur HT HSS-E Blind-Hole Tap

Walter has expanded its popular Paradur HT HSS-E blind-hole tap range by adding UNC thread dimensions. Previously available in dimensions M4-M36 and M10×1-M33×2, Walter has now expanded the range of the taps to include dimensions UNC 1/4-UNC 1.

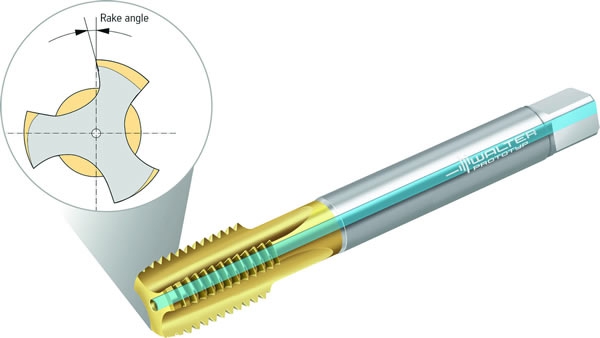

Walter has expanded its popular Paradur HT HSS-E blind-hole tap range by adding UNC thread dimensions. Previously available in dimensions M4-M36 and M10×1-M33×2, Walter has now expanded the range of the taps to include dimensions UNC 1/4-UNC 1. These new HSS-E taps are particularly well suited to cutting deep threads of up to 3.5 × D. Like their predecessors, they include performance enhancing features such as straight flutes, axial through coolant, and a TiN coating.

Walter has expanded its popular Paradur HT HSS-E blind-hole tap range by adding UNC thread dimensions. Previously available in dimensions M4-M36 and M10×1-M33×2, Walter has now expanded the range of the taps to include dimensions UNC 1/4-UNC 1. These new HSS-E taps are particularly well suited to cutting deep threads of up to 3.5 × D. Like their predecessors, they include performance enhancing features such as straight flutes, axial through coolant, and a TiN coating.

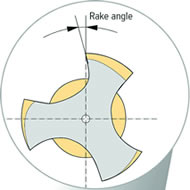

The specially designed cutting-edge geometry of the Paradur HT tap range affords excellent chip control. Axial through coolant reliably flushes short chips out of blind-holes. Ideal for machining steel with tensile strength of 98-200 kpsi (200-410 HB) and for cast iron, especially for GJS (GGG). The new tools offer a number of benefits for the user.

For one thing, "birdnesting" of chips is no longer an issue, which translates to high process reliability. Enhanced tool life significantly reduces machine downtime which is perfect for production environments using minimal manpower. Paradur HT taps are also cost-effective, while at the same time performance enhancing. These taps are typically used in the energy and in general metalworking industries.