Contact Details

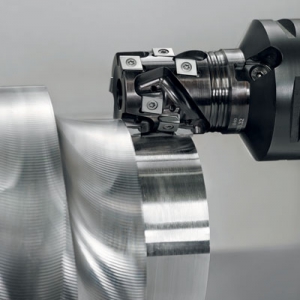

Walter has introduced new parting blade adapters for BMT/DO machines that ensure precision cooling of both the insert and the parting blade, thus improving chip control and tool life, and helping to increase productivity. With the Walter design, the coolant flows through the adapter directly into and through the parting blade to the cutting zone. An O-ring seal ensures that the coolant transfers efficiently and with no loss of pressure. In addition, for particular applications the adapters can also be used with external cooling, either alone or in conjunction with internal cooling. This is done simply by adjusting the coolant nozzle.

Installing the new parting blade adapters requires only a single bracket, whether the adapters are installed in the standard position or overhead. As an additional benefit, the adapter has adjustable center height for each individual workpiece within a range of ±0.020 in. (±0.5 mm). This allows an exact center position to be set on any workpiece, without additional tasks.

The precision coolant supply ensures excellent chip control and minimal tool wear. Machine productivity is increased by minimizing downtime to clear large chip volumes. The robust holder allows machining in any position required, minimizing vibration during operation.

Walter's new BMT/DO parting blade adapters work with a coolant pressure of 145 to 1,160 psi. This means that they can be used on virtually any machine with a BMT interface.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

PRODUCTS

PRODUCTS