Contact Details

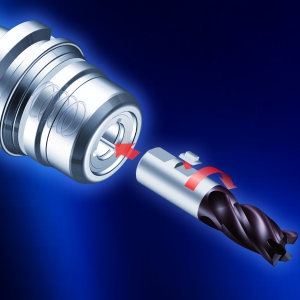

BIG KAISER Precision Tooling is adding more than 30 pressed-geometry carbide inserts for its tools. The new insert design is the result of extensive research and testing.

The new grades and geometries offer:

- Improved chip control due to optimized chip breakers, even when boring gummy materials like low-carbon or stainless steel

- Improved coatings for increased speed and better wear resistance

- More positive cutting geometries to reduce cutting forces, chatter and vibration when used in deep-hole boring operations

- Longer tool life

- Up to 20% savings when compared to current grades

BIG KAISER offers a range of insert grades and geometries for rough and finish boring, grooving and precision cutting, including indexable inserts.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS