Contact Details

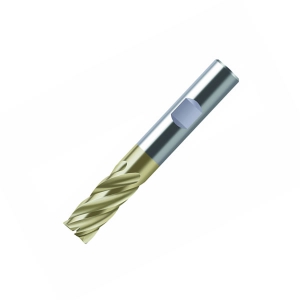

Walter USA LLC has introduced the Walter Prototyp Proto-max ST solid carbide end mill designed to provide superior performance in the machining of steel.

Productivity enhancing features allow this tough new end mill to achieve material removal rates up to 50 percent greater than standard solid carbide end mills. These include an optimized geometry that provides enhanced stability for the cutting edges, and a special surface treatment on the shank for a firm grip. In addition, there is a new type of coating with a zirconium nitrite-based surface layer. Due to its chemical composition the coating has a lower affinity with steel, resisting build-up at the edges and boosting tool life.

The new Proto-max ST is available in a range of diameters from 1⁄16-¾-in, (2-20mm), and in three and four flute designs. Variable flute spacing on the four flute model reduces harmonics that can cause vibration. There is a 45 degree helix angle on the three flute design while the four flute design has a 50 degree helix angle, both of which promote improved chip evacuation and surface finish. The three flute tool permits slotting depths of up to 2xD, with up to 1.5xD for the four flute tool.

Taken together, Proto-max ST design features reduce cutting forces and spindle loading. This enables the tool to be used effectively in less-than-stable clamping arrangements or where there are irregularities in the workpiece. This is a particular advantage on less robust machines.

In addition to its primary steel application, the Proto-max ST can be used effectively on stainless steels. A version of the tool for hardened steel (ISO-H) is also available.

Related Glossary Terms

- helix angle

helix angle

Angle that the tool’s leading edge makes with the plane of its centerline.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

PRODUCTS

PRODUCTS