Pyramid Abrasives

Pyramid Abrasives

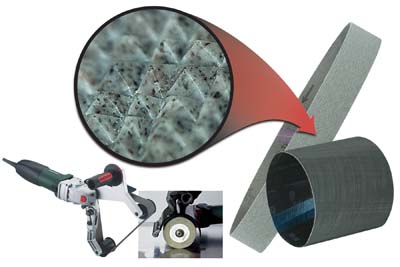

Metabo Corp. has introduced a line of Pyramid abrasives for use with its INOX tools that offer a better, more consistent finish than traditional metalworking abrasives, while providing high stock removal.

Metabo Corp. has introduced a line of Pyramid abrasives for use with its INOX tools that offer a better, more consistent finish than traditional metalworking abrasives, while providing high stock removal.

Unlike traditional abrasives that have material applied at random, Metabo's new aluminum oxide Pyramid abrasives feature a three-dimensional, structured geometric placement of the grains.

The calculated, geometric design allows finer grit sizes to remove more material, while giving work surfaces a consistent, even finish. Users can skip certain intermediary grit sizes to achieve the final finish faster, resulting in significantly reduced work time as well as increased service life of the belts and discs.

Available in 120, 280, 400, 600, 1200 and 2000 grit as well as in both belt and hook and loop disc design, Pyramid abrasives are ideal for use with Metabo's RBE12-180 pipe and tube sander, SE12-115 Burnisher and WE14-125 INOX angle grinder. These unique abrasives can also be used with other metalworking tools on the market.

Metabo's Pyramid abrasives are ideal for use on stainless steels, carbon steels, aluminum as well as other soft metals to perform a number of finishing applications in metalworking, including handrails, piping and decorative finishing applications.