Contact Details

BIG KAISER Precision Tooling Inc., Hoffman Estates, Ill., this month introduced the RBX12 Air Power Spindle, a high-speed, air-driven spindle said to be capable of achieving a variable rotational speed of 100,000rpm to 120,000rpm, according to a BIG KAISER news release issued Jan. 18.

Operating at such high speeds helps to improve machining accuracy, enhance surface finish, significantly lengthen tool life, as well as reduce wear on the cutting tool because the cutting tool will be running at the speeds intended, according to BIG KAISER. High-speed operation also is said to reduce processing time.

In various trials, the RBX12 was able to reduce machining time by more than 300 percent because of its high rotational speed.

Produced by BIG Daishowa Seiki, the new air-driven spindle reportedly is a cost-effective way to upgrade existing machines to perform high-speed micromachining in a normal machining center because the tool is driven by air supplied through a stop block, or through the machine spindle. As no rotation of the machining center spindle is required, the machine tool spindle can be used without wear, according to BIG KAISER.

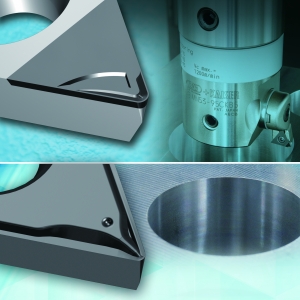

Due to its ceramic ball bearings and ultra-precise collet system, the runout accuracy of the RBX12 enables ultra-thin wall cutting. The AA-grade Mega Micro Collet guarantees 1µm runout at the collet nose, and the 0.004" collapsibility ensures a near-perfect concentric clamping of a micro-tool shank.

"For micromachining applications, the new RBX12 means that companies can get the most out of their existing equipment, achieving ultra-high levels of precision and speed," said Jack Burley, BIG KAISER's vice president of sales and engineering.

The RBX12 is available with BCV40, BBT30/40 and HSK-A63/F63/E32 interfaces. Models not requiring a stop block have an extremely small body diameter of Ø32mm (Ø1.260").

Related Glossary Terms

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS