Ready2Probe Software Application

Ready2Probe Software Application

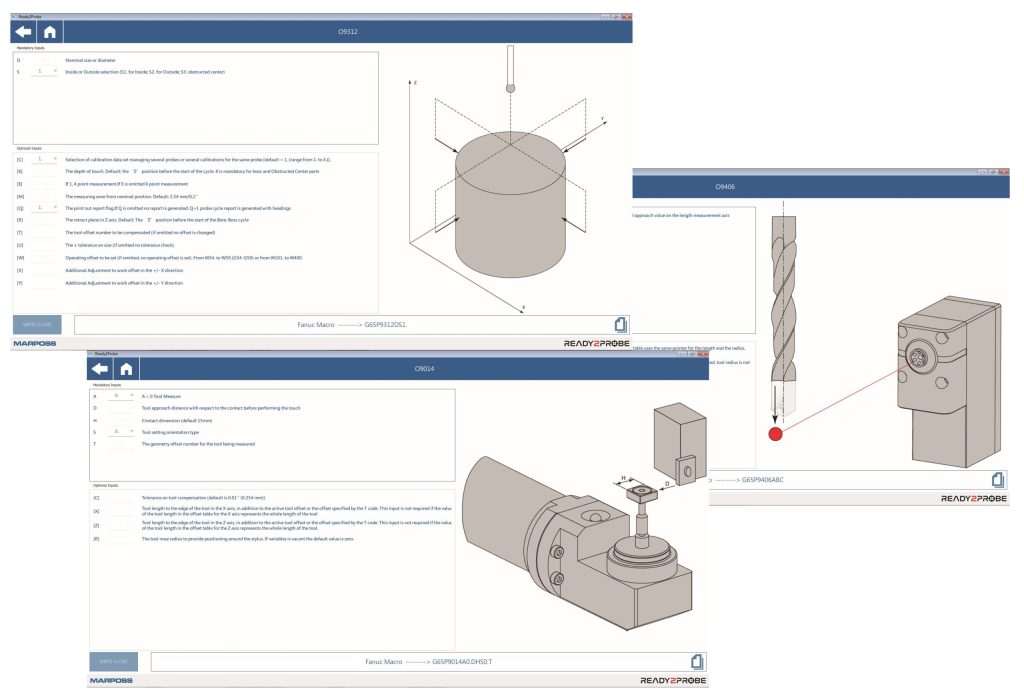

Marposs Corp. has announced its Ready2Probe software application to assist CNC users when programming cycles for measuring and checking components and tools using Mida spindle probes, lasers, TBD (Tool Breakage Detector) and VTS (Visual Tool Setter). Using simple-to-understand icons and menus, Ready2Probe assists users in commands and codes to generate the measurement cycle within seconds, based upon the machine tool part program. This helps to reduce programming time and errors when generating G code while improving quality assurance.

Marposs Corp. has announced its Ready2Probe software application to assist CNC users when programming cycles for measuring and checking components and tools using Mida spindle probes, lasers, TBD (Tool Breakage Detector) and VTS (Visual Tool Setter). Using simple-to-understand icons and menus, Ready2Probe assists users in commands and codes to generate the measurement cycle within seconds, based upon the machine tool part program. This helps to reduce programming time and errors when generating G code while improving quality assurance.

Ready2Probe is a Windows-based application that is compatible with the CNC control interface or a computer. Upon initiation of the Ready2Probe program, users can interact with all of the Mida products. The user then selects the from a calibration, automatic or manual cycle. The software then prompts the user to input cycle time information along with an option to input additional requirements. A macro string is then generated from this information, which the user can copy or automatically transfer into a part program. If needed, the user can also write the macro directly into the CNC by clicking a single button.

The software is so intuitive that even a person with minimal knowledge of Marposs measuring cycles can use it. In addition to Windows availability, the software application is being developed for use on smart phones and tablets. Mobile applications are already available for FANUC CNC users' running Android 4.1 and up and iOS 10.0 or later, offering easy accessibility on the shop floor.