SGX Plasma and Oxy-Fuel Cutting Machine

SGX Plasma and Oxy-Fuel Cutting Machine

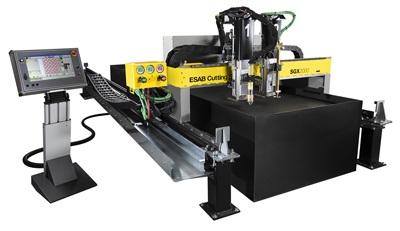

ESAB Cutting Systems introduces SGX, a compact, automated cutting machine for plasma and oxy-fuel cutting.

ESAB Cutting Systems introduces SGX, a compact, automated cutting machine for plasma and oxy-fuel cutting. The system is designed with ESAB's technology made affordable for the small fabricator or manufacturer. SGX is a rugged, high-performance machine that carries up to three tool stations, including up to two oxy-fuel torches and one plasma station that can be equipped with ESAB's m3-IGC Precision Plasma System for high-quality plasma cutting. Advanced features include the easy-to-use Vision T5 touch-screen CNC with built-in automatic nesting, as well as automatic gas controls and plasma automation powered by m3 Plasma technology.

Performance and accuracy are assured with a heavy steel beam, precision machined mating surfaces, and linear rail. This rugged design ensures smooth motion, accuracy and long term machine durability. SGX enables higher productivity with rapid cut-to-cut cycle times through the integration of dual-side, high-speed AC drives and a fast torch lifter.

The compact design of the SGX cutting machine minimizes floor space requirements. One-meter rail increments keep the footprint small to maximize production space.

Simple, automated operation is achieved with the built-in process database in the Vision T5 CNC, which fully integrates ESAB plasma and oxy-fuel process controls into an easy-to-use touch-screen interface.

The oxy-fuel gas control automatically switches between low preheat and high preheat pressure. Ease-on cutting oxygen allows for piercing of thicker materials. Gas controls are conveniently located at the side of the machine where the operator has easy access and can see the torches while making adjustments.

SGX can be configured with a range of plasma options, from simple air-plasma systems up to fully automatic 360 Amp multigas plasma systems. The machine can be equipped with ESAB's m3 Plasma for cutting up to 50mm (2") in mild steel. The m3 Plasma system achieves superior cutting results over a wide range of material types and thicknesses, and produces a high quality cut face with low dross, requiring little secondary clean up. It features an automatic gas control integrated with the process database on the CNC for fast and easy process setup without the guesswork.

SGX is available in sizes to cover plates up to 2500mm (8 ft.) wide, and up to two 6000mm (20 ft.) plates end-to-end. ESAB's newest cutting system is offered with a choice of downdraft tables or water tables for dry or under-water plasma cutting.