SMARTstop Master Jaw Set

SMARTstop Master Jaw Set

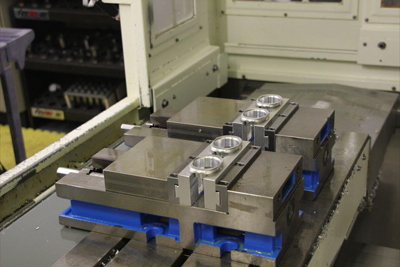

Bellatex Industries' CARVEsmart has added a fully accessorized 4" tool steel master jaw set, SMARTstop for repetitive set ups, PERMAjaw a flippable ductile cast iron jaw and two new extruded aluminum profiles and new cut-to-any-length 1-½"W x 2"H and a 1"W x 1.71"H flippable extrusions.

Bellatex Industries' CARVEsmart has added a fully accessorized 4" tool steel master jaw set, SMARTstop for repetitive set ups, PERMAjaw a flippable ductile cast iron jaw and two new extruded aluminum profiles and new cut-to-any-length 1-½"W x 2"H and a 1"W x 1.71"H flippable extrusions. The CARVEsmart system is designed for production and tool-room applications replacing the often cumbersome, conventional method of attaching vise jaws to a vise using face mounted cap screws.

CARVEsmart employs three, from the top, channeled clamping elements with a dovetailed jaw design that quickly couples machineable or hard jaws. CARVEsmart dramatically reduces set-up time, improves set-up reliability and quality. CARVEsmart's dovetailed aluminum extruded jaw stock has no face mounting cap screws to dodge. This makes the soft jaw a fully machineable, inexpensive cut to any length vise jaw.

SMARTstop is a highly repeatable, front loading, internal to the jaw, vertical slot and dowel pin location system included in 4" and 6" CARVEsmart steel ground master jaw sets. Step and carved jaws will repeat +/-0.0003" when replaced in the original master jaw. Operators can dowel pin the aluminum jaws they wish to reuse or purchase SMARTstopped (pre-pinned) 4" and 6" jaws in all five aluminum profiles, 1018 or ductile cast iron jaws.

PERMAjaw is a SMARTstopped, ductile cast iron jaw set. It is ¾"W x 1.71"H and flips to expose a fresh face. It will repeat in the same master jaw +/-0.0003". PERMAjaw is best for repeating jobs and matched to the spindle step jaws.

CARVEsmart offers economical, extruded aluminum, dovetailed jaw stock in five profiles of 1"W x 1.71"H flippable, ¾" x 2", 1" x 2-¼", 1-½" x 2", and 2" x 3" in lengths of 4, 6, 31 and 94 inches. Also available is ¾"W x 2"H dovetailed 1018 steel bar stock in 4", 6" and 31" lengths. With CARVEsmart only one saw cut is necessary for any length jaw from 1" to 94". This can reduce jaw cost by half or more compared to purchasing a commercially made jaw or making them in-house.

CARVEsmart #MJSSG4 4 inch 4140 ground tool steel master jaw set, designed for production work, is ground flat and parallel within .0002". This high quality set is fully accessorized with all SMARTstop options and accepts all jaw stock.

Recutting the female form with each part run matches the jaw and vise perfectly to the spindle. CARVEsmart dramatically reduces setup time, improves set-up reliability and quality. This makes the CARVEsmart system ideal for shops that change vise jaws often; running repeating and tight tolerance work.