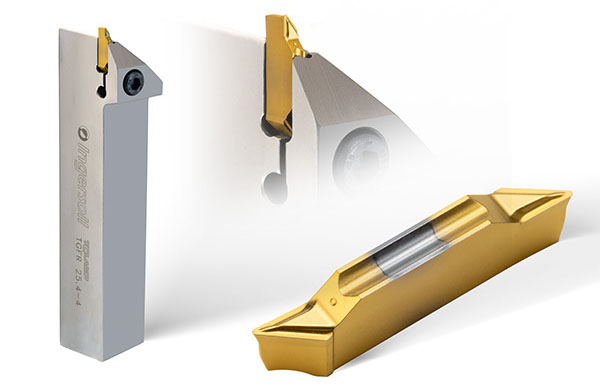

TClamp VT

TClamp VT

In addition to operating on narrow grooving on typical CNC lathes, the new V-shaped TDMV inserts are suitable with a wide range of applications on Swiss automatic lathes, with a concentration on miniature product machining. The V-shaped TDMV insert line is a multi-purpose option and the optimal tool for innovation in the groove machining segment in order to meet various customers' needs.

Ingersoll introduces the V-type T-CLAMP insert that maximizes productivity by minimizing tool change through multifunctional machining.

In addition to operating on narrow grooving on typical CNC lathes, the new V-shaped TDMV inserts are suitable with a wide range of applications on Swiss automatic lathes, with a concentration on miniature product machining. The V-shaped TDMV insert line is a multi-purpose option and the optimal tool for innovation in the groove machining segment in order to meet various customers' needs.

Features & Benefits

-

Versatile chip breaker: forward/backward turning, profiling, end facing and parting

-

Optimized chip breaker design for bi-directional turning enables superior chip control

-

Insert's 2.8 mm edge width allows for a variety of tasks in tight spaces

-

Roughing and finishing capable with a cutting depth of up to 2.5 mm

-

Available in 4 insert types: R/L-handed, Corner R0.2, R0.4

-

Multi-application machining reduces tool cost and equipment downtime while maximizing productivity gains

-

Compatible with standard TGFR/L holders, maximizing performance when using internal high-pressure feed-type holders