Contact Details

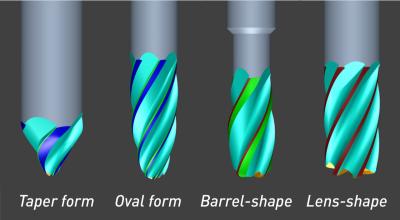

Discover new possibilities in machining with the latest Barrel Shape Ballnose (BSB) tooltype in ANCA’s up-to-the-minute ToolRoom software. The latest enhancement also includes revamped Double Corner Radius (DCR) Endmills. These endmills constitute a new tool class for machining excellence. Barrel and lens shapes and taper and oval forms are relative market newcomers and are predominantly used in the die mould, aerospace, general machining and power generation industries.

ANCA Software Product Manager, Thomson Mathew said: “The ability to create endmills with a larger-radius edge, permits greater stepover increments. This enables machining with a larger crossover pitch during pre-finishing and finishing operations – improving productivity.”

Shorter cutting distances mean it’s almost like a two for one coupon for longer tool life and faster cycle times.

Thomson adds: “Replacing conventional ballnose and corner radius applications with the large tangential form radius simulates these applications but the outsized cutting diameter is what saves cycle time and cost; and the resulting surface finish is better as well.”

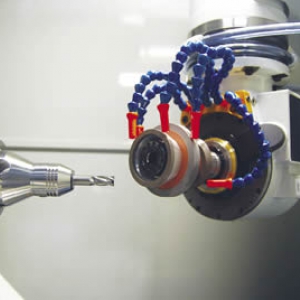

“Bringing these new endmills together with the expert advantages of ToolRoom such as iView and laser compensation, designer edge ballnose, variable helix and tool balancing sets tool manufacturers up with a complete solution and is unique to ANCA software. In addition, a special fluting operation ensures a constant hook angle all the way along the trajectory of the cutting edge resulting in vibration-free tools, with less wear and tear during machining.”

Innovation and flexibility in ANCA’s software has always been an intrinsic partner to tool machines’ functionality. With a legacy of first-to-market software features, this enhancement continues to advance the sophistication and application diversity of ANCA’s dedicated cutting tool software package. Clever features offer customers the machining capabilities needed for today’s market.

Thomson adds: “ANCA has been leading the industry in terms of new features, cycles, cutting tool geometry and functionality in our cutter grinder software for over two decades and this latest release extends this further.”

The upgrade offers wizard-based design for user-friendly operation

Manufacturing complex, sophisticated endmills is made easy with wizard-based BSB design in ToolRoom, suitable also for catalog production.

BSB and DCR tool types are high performance endmill cutters, mainly used for finishing requiring high accuracies. They may be more familiar to some as circular segment or high feed endmills. In the current market, cutting tool manufacturers may be looking to enter new markets and this software release makes diversification with high-quality specialist tools attainable.

This sought after enhancement retains ANCA’s renowned software user-friendliness and completes the ToolRoom RN34 endmill package.

The features of the new market release encompass compensation and accuracy

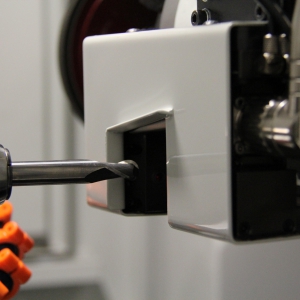

Compensation methods are covered as ANCA supports manual, iView and LaserPlus compensation for all geometry, as these tools are highly accurate. Both ball radius and tangential barrel form radius can be maintained within +/-0.002 mm using LaserPlus. This accuracy can also be maintained in batch grinding with automatic in-process compensation for large volume production on machines with LaserPlus.

The wizard-based design also provides the option to scale tools and add various other operations like roughing or chip breakers. Wizard support is available for oval form, taper form and also a custom form for specials. A static view gives parameter inputs for geometry description and there is also a dynamic view available to visualize the geometry as and when parameters are entered.

There are multiple practical advantages of ToolRoom software for cutting tool manufacturers:

- iView and laser compensation for large volume manufacturing

- Designer edge ballnose for aggressive cutting

- Variable helix/index with radial margin option for fluting cycles.

- Tool balancing for variable helix/index tools for chatter free cutting

- Constant hook along cutting-edge trajectory (special flute from solid)

- Very user-friendly GUI with static and dynamic view specially for catalog tools

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- fluting

fluting

Cutting straight or spiral grooves in drills, endmills, reamers and taps to improve cutting action and remove chips.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

PRODUCTS

PRODUCTS