Contact Details

BIG KAISER’s UNIFLEX system is a 3D zero-point clamping system designed to allow parts with curved surfaces to be held rigidly for various operations and be adjusted to different height requirements. The UNIFLEX system is available in two diameters: 25.4mm and 50mm.

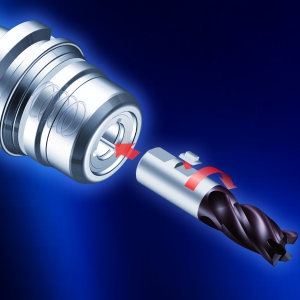

BIG KAISER is accelerating workholding technology to match the level of the ever-more popular and accessible multiaxis machining. The UNIFLEX system is composed of a clamping ball and collar that are attached to the underside of a part or fixture. The clamping ball is a hardened steel ball of the same type found in heavy-duty industrial bearings. This material prevents peening or denting of its surface with normal use.

Once the clamping ball and collar are attached, the part and fixture are then lowered onto either a clamping base or a clamping extension. The clamping collar is then rotated to tighten the six bearing balls on to the main ball. If the part or fixture is warped or needs to be set at an angle, the clamping ball can pivot up to 15° of the vertical with 18mm of height adjustability or 40° with 20mm of height adjustability.

The UNIFLEX System 50mm has an increased clamping ball size, which allows it to work with larger, heavier, uneven parts and provides more rigidity. Balls are offered in two types: location type, which uses a 25mm-dia. location collar, while a grip type has serrations to grab the part. Grip type is not to be used on finished surfaces.

This system provides vibration-free holding of the part when multiple clamping is used and has low-wear against tools. It also can stabilize the workpieces without obstructing access to the top and sides of the part. The two sizes available enable users to work with small or large workpieces like weldments and castings.

PRODUCTS

PRODUCTS