Contact Details

C.O.R.E. from UNITED GRINDING Group Nominated in UX Design Awards 2022

Customer Oriented REvolution (C.O.R.E.), a revolutionary product innovation from the UNITED GRINDING Group, has been nominated in the UX Design Awards for its outstanding user and customer experience. The UX Design Awards 2022 panel selected it from a pool of 300 submissions across 58 countries.

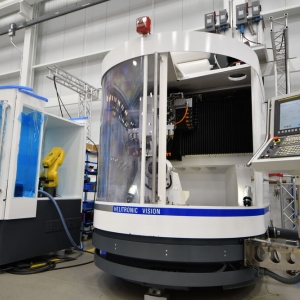

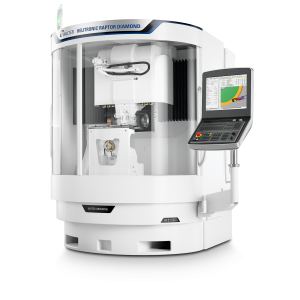

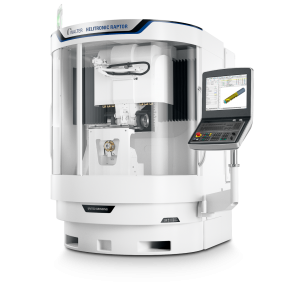

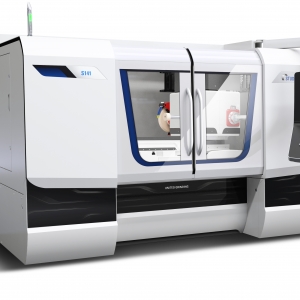

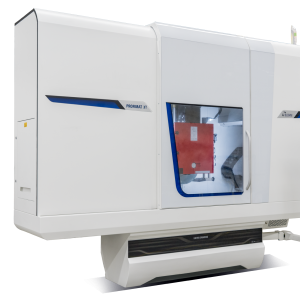

C.O.R.E. brings to life a new machine interaction concept based on a modern hardware and software architecture. It standardizes the operation of all machine tools from the UNITED GRINDING Group, with a new 24-inch multi-touch C.O.R.E. panel that offers intuitive controls—similar to a smartphone—and personalized customization options. The clean design of the C.O.R.E. panel features only a few buttons, resulting in clean visuals. The integrated front camera allows for quick and easy support via video calls. The virtual function keys are only displayed when needed, further reducing complexity and eliminating potential sources of error. The role-specific interface, with the option of limiting the display depending on who’s using it, also simplifies machine operation. In this way, C.O.R.E. improves the working experience both for the machine's operators as well as setup and maintenance personnel.

Nomination for Outstanding User and Customer Experience

The merits of C.O.R.E. impressed the jury of the UX Design Awards 2022, earning it a nomination from among 300 products and projects from 58 nations. The award is renowned as the top global competition for outstanding experiences, presented by the International Design Center Berlin (IDZ).

“We are quite proud of this nomination,” says Christoph Plüss, CTO of the UNITED GRINDING Group. "For years, a large group-wide team of software, hardware and process experts have worked diligently on C.O.R.E., with the target to create real added value for our customers in the area of user experience. We're very pleased to hear that we have succeeded."

Just the Beginning

Nomination aside, C.O.R.E. encompasses much more than revolutionary machine operation. The groundbreaking hardware and software architecture opens up new possibilities for networking, controlling and monitoring the production process, and thus for process optimization. It also lays the foundation for the operation of modern IoT applications, thus opening the door to the digital future. Plüss promises: "This is just the beginning. We are constantly working on C.O.R.E., looking more improvements to make our customers’ work even easier." The UNITED GRINDING Group has set a goal to actively shape the digital future and make its customers more successful along the way.

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

PRODUCTS

PRODUCTS