Contact Details

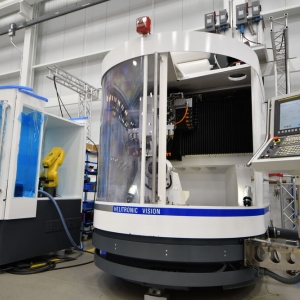

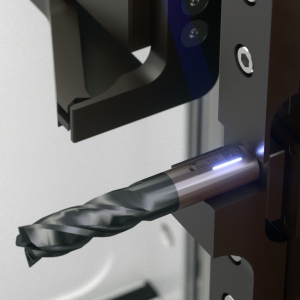

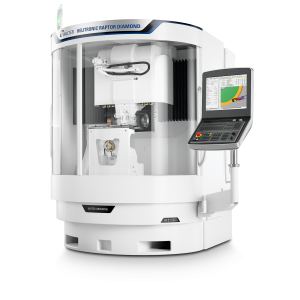

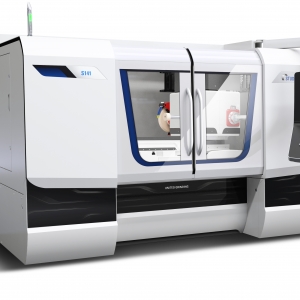

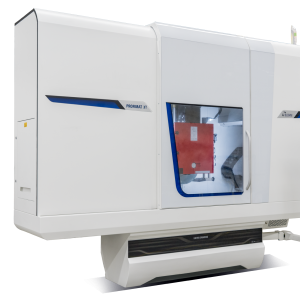

The new Walter Helitronic Raptor from United Grinding Group is a flexible, cost-effective tool grinding machine. Created for the grinding and re-sharpening of rotationally symmetrical tools for the metal and wood industries, the new Helitronic Raptor offers both automation-ready flexibility and an economical, universal design.

Developed with the re-sharpening sector of the rotationally symmetrical tool market in mind, the Walter Helitronic Raptor is particularly well-suited for shops that do not require features such as automatic tool support systems or automatic grinding wheel changers, but still need a high degree of flexibility in the working area for diverse types of tools. The new machine ensures that manufacturers have access to Walter quality with exactly the features they need for part-production and re-sharpening success.

The Walter Helitronic Raptor has a 15.4 hp (11.5 kW) spindle and a work envelope that can accommodate tools up to 12.6" (320 mm) in diameter and 11.0" (280 mm) in length, including end face operations. For enhanced tool grinding efficiency, from tool design to part production as well as re-sharpening, the machine uses Walter Helitronic Tool Studio.

In addition to its low-vibration gray cast iron frame and gantry-type construction, the Helitronic Raptor is designed to accommodate a range of options, including top loaders with up to 500-tool capacities integrated in the working area. Other options include glass scales, A-axis torque drive, a grinding wheel measuring probe and a manual support steady rest.

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

- steady rest

steady rest

Supports long, thin or flexible work being turned on a lathe. Mounts on the bed’s ways and, unlike a follower rest, remains at the point where mounted. See follower rest.

- work envelope

work envelope

Cube, sphere, cylinder or other physical space within which the cutting tool is capable of reaching.

PRODUCTS

PRODUCTS