Contact Details

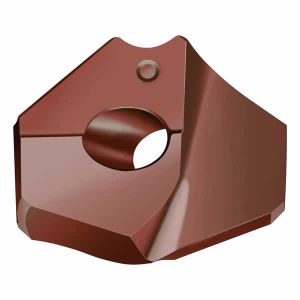

Walter USA LLC has introduced the Walter Valenite F4050 cartridge type cutter, an innovative new approach to the challenges of high-speed milling of non-ferrous materials. Features of the F4050 include the use of high-tensile steel cartridges with brazed PCD carbide tips. An adjusting key guarantees aµm-precise runout of the cartridges. Toolsetting is done through clamping screws which are tightened according to defined torques, enabling high limiting speeds. Fine balancing screws also ensure a high balance class. Importantly, the F4050 is designed and built to allow all adjustments to be done quickly and easily and thus help boost the tool's productivity.

F4050 is available in diameters ranging from 80 to 200mm. A carbide chip deflector supports the significant level of chip production in both roughing and finishing operations. The tool is equally productive at maximum cutting speeds in the range from 5000 to 7000 m/min.

Cartridges with a 90°Clearance angle and cutting depths of up to 4mm, or cartridges with a 75°Clearance angle and cutting depths of up to 1.1mm are currently available. These enable both shoulder mill and face mill operations. In addition, Walter also provides a broad finishing cartridge for applications where a very high quality surface finish is critical.

Applications for the new milling cutter include high volume machining of non-ferrous metals such as hypereutectic and hypoeutectic aluminum alloys in the automotive and general machining sectors. Typical components would be engine blocks, cylinder heads and die-cast aluminum gearbox housings. Depending on the applications, special PCD varieties and tool diameters are also available.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum alloys

aluminum alloys

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

PRODUCTS

PRODUCTS