Contact Details

Walter has added indexable inserts to the range of products available via the Walter Xpress fast delivery service. Previously the special custom solutions available with Walter Xpress had been limited to round tools and tools that hold indexable inserts.

Additionally, the tools were required to be “close to the standard tools.” Now, Walter offers its customers the benefits of Xpress for indexable inserts too. These benefits include short delivery times of three to four weeks, depending on the product. These special inserts then allow customers to reduce the total number of tools required to finish a component and provide greater certainty when planning because of shorter delivery times.

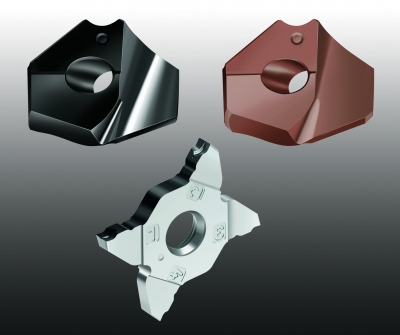

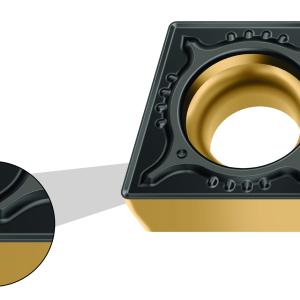

The indexable inserts available via Walter Xpress include the high-performance P600x replaceable-tip drilling inserts and Walter Cut multiple-edge MX grooving inserts. The P600x drilling inserts are offered in quantities of 10 to 200 pieces with a diameter from 0.472 in (12 mm) to 1.496 in (37.99 mm). These are suitable for holes with a tolerance of IT8 or IT9 – either in intermediate steps between the nominal sizes or with a special feature such as a chamfer or a corner radius.

Also, the four-edged indexable inserts in the Walter Cut MX grooving system are offered in quantities of 10 to 50 pieces. These have a maximum cutting depth of 0.24 in (6 mm) and a cutting width of from 0.04 in (1mm) to 0.13 in (3.3 mm). The specials for MX inserts can include steps between nominal sizes or a feature such as a full radius, straight edge or a chamfer between 30 and 50°.

Related Glossary Terms

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

PRODUCTS

PRODUCTS