Contact Details

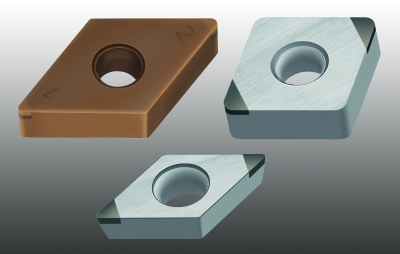

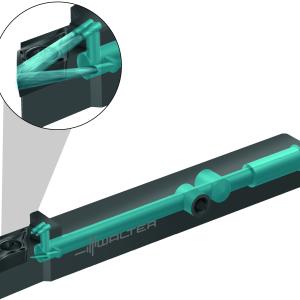

Walter has introduced new PCBN grades for improved turning of hardened steel up to 65 HRC. These grades (WBH10C, WBH10 and WBH20) provide users with an array of benefits. High-quality surface finish due to unique new wiper geometry (MW2) and long tool life with the new TiAlSiN-coated grade (WBH10C) are just some of these benefits. Inserts with laser etched chipbreaker geometry TM-M2 are also available.

All inserts are ground for exceptional process reliability. These new grades are available in both positive and negative inserts and are suitable for both continuous and interrupted cuts.

Additionally, Walter has also introduced WBS10, a new PCBN grade for finishing high-temperature superalloys in either continuous or interrupted cuts. Available in both positive and negative inserts, WBS10 features sharp “EM2” microgeometry and superfine grain with ceramic binder.

Related Glossary Terms

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS