Contact Details

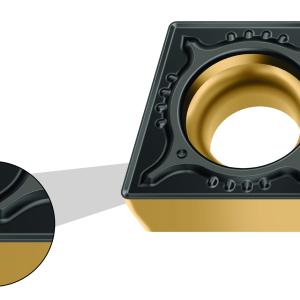

Walter has introduced WSM01, a premier grade for demanding machining applications. Coupled with Walter’s new MS3 negative geometry, it produces burr-free results with high surface finish quality in the hardest materials.

The WSM01 difference stems from its HIPIMS PVD coating method. Unlike standard PVD coating, which deposits discrete droplets upon the target surface, HiPIMS (High Power Impulse Magnetron Sputtering) PVD coating produces extremely smooth surfaces leading to reduced friction in machining. The new coating is characterized by an excellent layer bonding and thickness distribution, reducing the tendency of "flaking." Extra smooth surface of the coating and extremely sharp cutting edges keep edge build-up to a minimum and ensure high surface finish quality.

This new insert is particularly suitable for machining unstable or thin-walled components. The MS3 insert is equipped with jet-guiding geometry to ensure optimum cooling directly on the cutting edge and is particularly well-suited to copy-turning applications and medium machining applications in aerospace, automotive and general metalworking industries.

The combination of the WSM01 grade’s HiPIMS PVD hard layer and the new MS3 geometry is ideal for machining ISO S materials with difficult cutting properties such as high temperature alloys, titanium alloys, cobalt-based alloys, and nickel-based alloys such as Inconel 718. A secondary application of this new grade is with ISO material groups M (stainless steels), N (nonferrous alloys such as aluminum) and P (steels).

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

PRODUCTS

PRODUCTS