Contact Details

Walter USA LLC has unveiled a series of new inserts to its Walter Xtra-tec Point Drill lineup, which reportedly provide the optimal drilling solution for the heat exchanger industry. Heat exchangers are used in the power generation industry, as well as oil and gas, refrigeration, and water treatment.

The drilling of tube and baffle plates are key elements in the manufacture of heat exchangers. Drilling often runs to great lengths, placing unique demands on the tools. These parts can be constructed from a variety of materials, making tooling considerations even more complex. Tube materials include soft ferrite steels, austenitic stainless steels, duplex stainless steels, nickel-based materials, cladded sheets and non-ferrous metals. For baffle plates, mainly soft ferrite steels and non-ferrous metals are used.

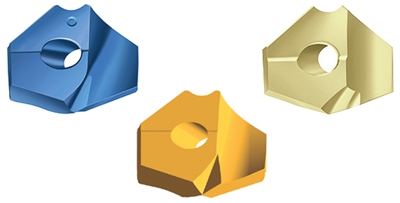

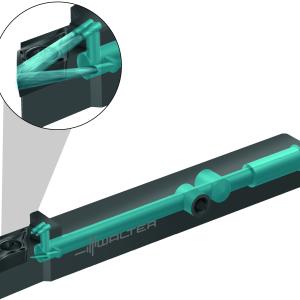

Walter now provides two types of Xtra-tec Point Drill inserts to meet these needs: The P6001 (Universal in grades WXP45 and WPP45C0), and the P6003 (Specialist in grade WMP35). Each is available in a wide variety of standard sizes.

These Xtra-tec Point Drill inserts' performance advantages can be traced to their precision ground geometry which yields high surface quality, and their self-centering effect and stabilizing lands resulting in close bore tolerances and precise cylindrical bores. Their secure insert clamping limits the possibility of vibration and boosts process reliability.

The inserts can tackle a wide variety of applications including drilling through and blind holes, drilling precision holes (tolerance of H8 is possible), stack drilling, drilling holes close to contour, and tap drill holes.

They are suitable for drilling in ISO material types P,M,K,N and S. And though they are the smart solution for heat exchanger drilling needs they also find application in the automotive, aerospace, and mold and die industries, as well as general metalworking.

Related Glossary Terms

- ferrite

ferrite

Solid solution of one or more elements in body-centered cubic iron. Unless otherwise designated, for instance, as chromium ferrite, the solute is generally assumed to be carbon. On an equilibrium diagram, there are two ferrite regions separated by an austenite area. The lower area is alpha ferrite and the upper area is delta ferrite. If there is no designation, alpha ferrite is assumed. Not more than 0.04 percent carbon can be dissolved in alpha iron. Ferrite is stable below 1,670º F (910º C); it is soft, highly ductile, and magnetic. Ferrite loses its magnetic property above 1,414º F (768º C).

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

PRODUCTS

PRODUCTS