In this column, I’ll talk about deep slotting. Slots, or grooves, are common features of machinery components, so much so that special cutters are available for machining slots.

As the ratio of the depth of the cut to the width of the cut increases, it’s helpful to understand the cutting forces involved in order to have a successful outcome in the manufacturing process. I make some parts that have a slot with the depth dimension 10 times the width dimension. The bottom photograph shows the part after slotting beside the finished part. It’s a knife for processing corrugated cardboard into folding boxes. The knife material is type A2 tool steel.

When cutting such a feature, a cutter that rotates like a circular saw or Woodruff keyseat cutter produces better results than a cutter like an endmill in which the axis of tool rotation is inside the slot. A circular cutter gives a better metal removal rate and better control of the slot width. Radial and tangential cutting forces are in the plane of the slot depth, so radial deflection of the tool will not alter the slot width. The cutter is designed to have small axial forces in the cut. This makes for quicker, more accurate machining. Note that care must be taken to make axial runout of the cutter setup acceptable. Axial runout of a circular cutter like this will increase the width of the cut.

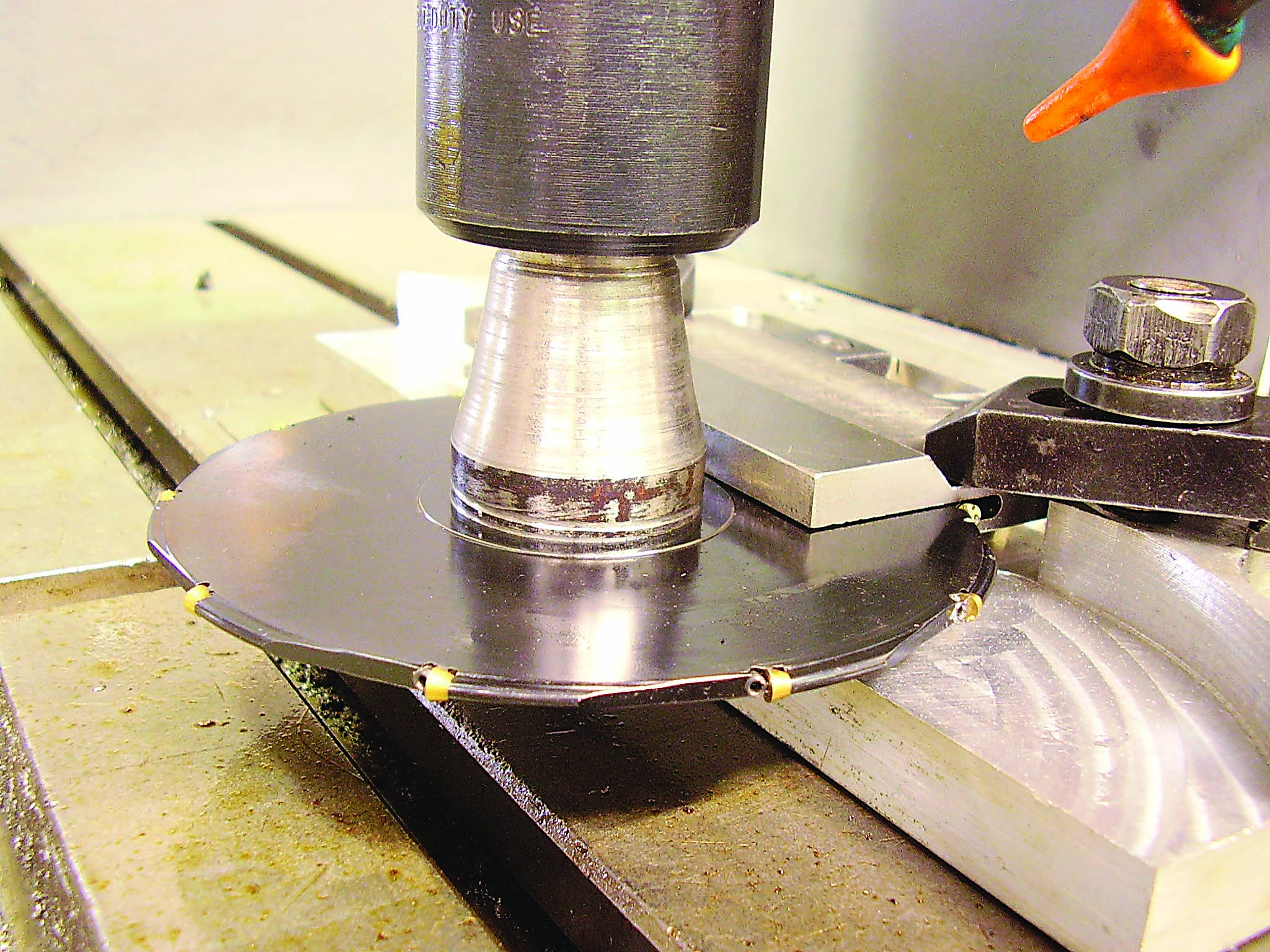

The slot has a full radius bottom. A circular cutter that mounts on a mandrel and uses round indexable inserts is a good choice for making this feature. The top photo shows the machining setup with the cutter in the slot. The fixture holds the part to be machined by two edge clamps and two T-slot clamps. The cutter uses round inserts that have diameters equal to the width of the slot so the finish slot size is easy to maintain.

This particular indexable cutter is made by Cutting Tool Technologies Inc. in Wilton, New Hampshire. CTT has an array of off-the-shelf indexable milling cutters for various operations. This cutter has a standard 31.75 mm (1.25") dia. center hole with a keyway. I made a mandrel with a Weldon shank so CTT’s tool could be mounted in an endmill holder and used on a milling machine with the cutter axis in the z direction. I use lots of flood coolant to wash chips away from the cut and prevent them from being re-cut. Plus, cool cutting edges last longer, which I like. I recommend a conventional milling direction when milling A2. Climb milling makes for higher cutting pressures.

I also make a similar part with a different slot width that does not match off-the-shelf round inserts. CTT sourced custom-diameter inserts and made a cutter to accept them. The prices were reasonable.

Related Glossary Terms

- circular saw

circular saw

Cutoff machine utilizing a circular blade with serrated teeth. See saw, sawing machine.

- climb milling ( down milling)

climb milling ( down milling)

Rotation of a milling tool in the same direction as the feed at the point of contact. Chips are cut to maximum thickness at the initial engagement of the cutter’s teeth with the workpiece and decrease in thickness at the end of engagement. See conventional milling.

- conventional milling ( up milling)

conventional milling ( up milling)

Cutter rotation is opposite that of the feed at the point of contact. Chips are cut at minimal thickness at the initial engagement of the cutter’s teeth with the workpiece and increase to a maximum thickness at the end of engagement. See climb milling.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- mandrel

mandrel

Workholder for turning that fits inside hollow workpieces. Types available include expanding, pin and threaded.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.