Innovative turning process for vertical lathes

Innovative turning process for vertical lathes

Competition in the automotive industry is driving the need for higher-quality parts and lower manufacturing costs. All aspects are affected, including turning.

Competition in the automotive industry is driving the need for higher-quality parts and lower manufacturing costs. All aspects are affected, including turning.

The Germany-based toolmaker Vandurit GmbH has addressed this challenge with its development of the rollFEED turning process. Vandurit has, in turn, collaborated with EMAG Salach (Germany) GmbH to use rollFEED exclusively with the vertical turning centers that EMAG builds. The process, which works with chuck diameters as large as 500mm (19.685"), provides a third axis and can be retrofitted to existing EMAG centers.

A major challenge the companies faced was satisfying customers' demand for processes that helped them machine parts with increasingly complex geometries. Existing processes required a lot of insert changes to meet the surface requirements of the parts.

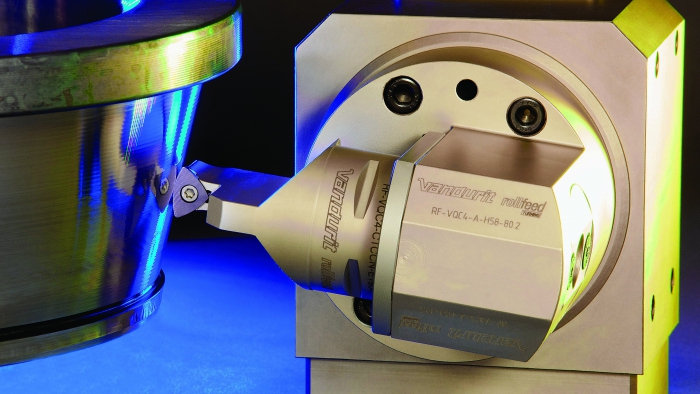

As an insert moves across the workpiece's surface, the point of contact along the tool's cutting edge moves. Image courtesy of EMAG USA.

Vandurit found that adding the third axis to the turning process allowed the insert to move while the part was being machined. "Now, a specially shaped rollFEED insert consisting of radial segments passes along the various sides of the part, one after the other," explained Maurice van den Hoonaard, Vandurit's managing director.

The capability provided by this third axis enables the turning tool to pivot. The machine's X and Z axes compensate for any center offset that results from the pivoting.

In addition, as the rollFEED insert moves across the surface of the workpiece, the point of contact along the tool's cutting edge moves. "Due to the uniformly or variably sized machining radius segments, it is possible to work with significantly higher feed rates," van den Hoonaard said. "In addition, the surface quality is better, all the way into the corners."

Another significant area of improvement is speed. According to Peter Loetzner, EMAG LLC USA's president and CEO, the rollFEED process is much faster—up to 90 percent—than turning operations that require several tools over many steps. "A complete machining process from three component sides is now possible with only one type of insert," he said. "As a result, the number of different tools used in production is lower, which makes many tool changes redundant—a true cost killer." Among the contours that can be produced are end faces and cylindrical surfaces, chamfers, and convex or concave surfaces.

For more information about EMAG LLC USA, Farmington Hills, Mich., call (248) 477-7440 or visit www.emag.com.