One size fits all

One size fits all

The pros and cons of turning with the "perfect" insert.

Fifteen years ago I wrote an article for CTE called "Lowering your grades." It argued that shops could save money by reducing insert inventory. The premise was that the productivity gains realized through use of the "perfect" insert for any given material would be eaten up by the setup time needed to change that insert and make the necessary feed and speed adjustments, program tweaks, tool registration and test cuts.

That argument still carries weight with some metalworking professionals. Shops that turn a range of materials can find themselves adrift in a

sea of cutting tool choices. Many struggle with bloated tooling inventories, insert obsolescence and cutting tools that get used for a single job, then spend eternity collecting dust in a forgotten corner of the toolcrib.

Courtesy of Walter USA

The good news is that insert costs haven't changed much since then. Due to improved manufacturing techniques, an 80° diamond that sold for $10 in the Reagan era is just a few dollars more today. And because cutting tools have improved, that insert will run longer than its predecessor from the 1980s, making it more likely you'll hang on to it once that 10-piece Inconel job is done.

My previous article used the example of a popular toolmaker with 54 grades of carbide. Today, that company offers twice as many grades and an even larger variety of shapes, edge preparations, nose radii, chipbreakers and through-coolant options. Of course, choice is a wonderful thing, but some might say: "Stop the madness."

Not so Fast

Chris Wills wouldn't be one of them. The turning products specialist for toolmaker Mitsubishi Materials U.S.A. Corp., Fountain Valley, Calif., said it's always important to optimize cutting tool and machine performance. "Whether it's a small job shop or a large company, American manufacturers are competing in a global market. Sacrificing production to improve changeover time is not a very smart choice."

While the expense of stocking inserts to cover every material contingency might seem prohibitive, cutting tools account, on average, for only 3 percent of the total production price of most machined parts, Wills said. While that percentage is small, it is an area that the accounting department tends to focus on, because inventory and carrying costs are easier to quantify than the nitty-gritty of the machining process.

Productivity is far more important, according to Wills. He argues that using the best insert available reduces cycle time and scrap and that the few extra minutes of setup time incurred as a result is negligible. However, operators must know which insert to use and how to apply it. Mitsubishi Materials counters the growing complexity of the manufacturing environment by offering training classes for its distributors and customers, including operators.

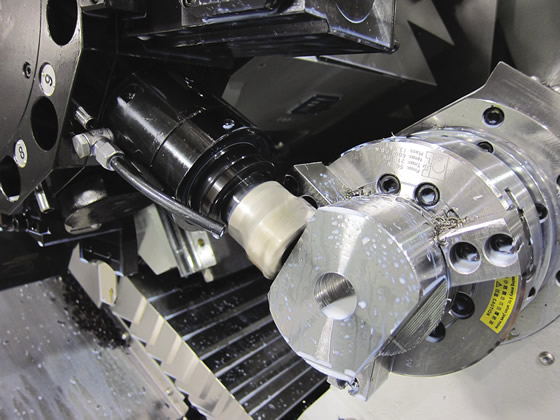

Courtesy of EXSYS Tool

A cutter tooled with general-purpose inserts can be used for a variety of milling operations on a mill/turn center.

"Quite often we find operators have never been educated on the different grades of carbide and how to optimize the machining process," Wills said. "It's important to show them the difference between PVD- and CVD-coated inserts, what chipbreaker and insert geometry to use and how to identify tool wear, among other factors."

Mitsubishi Materials stresses the need to create reports whenever a new insert or other cutting tool is tested. Wills said shops might think they're saving money by going with a general-purpose grade but it can cost more in lost productivity. It's only by analyzing part output, tool life and insert cost that the best decision can be made. "We've seen situations where a shop buys a toolholder and gets the inserts for free," he said. "With a test report, we've proven that had they purchased an optimized insert instead, they would have saved money."

There's more to this debate than carbide. Optimized cutting calls for high-performance toolholders as well. Toolholder providers are constantly improving their wares, and sticking with the status quo or a one-size-fits-all approach is a recipe for mediocrity or worse. That's because, as a cutting tool's performance increases, so must its support systems. Insert pockets carry heavier loads, clamps must securely prevent movement, and the toolholder body itself may need an upgrade.

Therefore, manufacturers that invest in the right tooling are better off in the long run. "Shops need to decide whether they'd rather be more streamlined or be stuck in the hole of constantly replacing perishable tools," said Scott Leitch, product support manager for EXSYS Tool Inc., San Antonio, Fla. "By choosing the right insert and the toolholder to go with it, shops will produce more parts in less time and, ultimately, save money on their production costs."

EXSYS markets quick-change toolholders. For shops concerned about the additional setup time incurred when swapping a turret full of steel-grade inserts for ones geared towards cast iron, quick-change is the answer, Leitch said. With a properly implemented quick-change strategy, one that utilizes tool life management and offline presetting, tool touch-off is avoided. This eliminates much of the argument against material-specific insert optimization.

"When somebody invests in quick-change systems, they should go into it with the understanding that there will be tooling in the crib that won't be used on a regular basis," he said. "The upside is always having that one particular tool ready to do a specific job and cut parts without downtime or the loss of performance seen when using general-purposegrade carbide."

General Purpose Gets a Boost

Kurt Ludeking, turning product manager for toolmaker Walter USA LLC, Waukesha, Wis., said there's a line that shops draw between using material-specific and general-purpose inserts, and grade advancements have pushed the line in favor of the general-purpose ones.

"A lot of machine shops see everything," he said. "One minute they're cutting low-carbon steel, next it's 17-4, after that they're cutting Inconel 625 or some other material they've never even heard of. They can't waste a lot of time figuring out how to run this stuff, especially with small lot sizes."

According to Ludeking, the answer is often a general-purpose carbide grade. This is particularly true for stainless steel and high-temperature alloys, both of which can be effectively cut with a CVD-coated carbide grade that straddles the fence between hardness and toughness. Someone who spends his days cutting Inconel and 316 stainless might say CVD-coated tools simply aren't sharp or lubricious enough to cut these sticky materials. Ludeking would have agreed with that person 10 years ago—but not today.

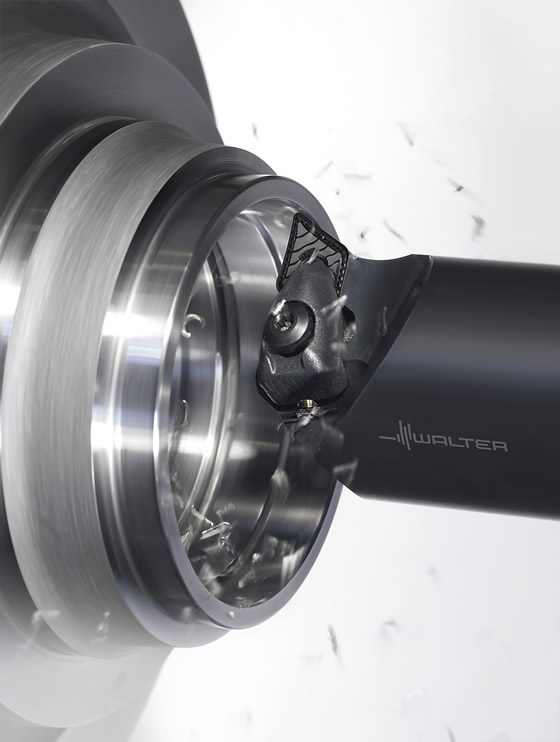

Courtesy of Walter USA

A general-purpose CVD-coated insert used in a boring application offers balance between toughness and wear resistance.

"What's changed is on the CVD side," he said. "We're able to tune the structure of the aluminum-oxide crystals so that we can achieve better heat and wear resistance than in previous generations of CVD. We've also developed better post-coating treatments." One example is a blasting process that creates compressive stresses in the coating surface to improve edge toughness and hold a sharper edge. "This is something we really couldn't do until the last few years."

The results aren't perfect, but they're pretty darn good. Ludeking said the worst case might be a 20 percent reduction of feeds and speeds compared to a grade that's tuned for a specific material, but if this saves 10 minutes of setup time on a job that runs 30 minutes, a general-purpose grade is a no-brainer. "With the advancements everyone's made in coating technology, it makes general-purpose inserts much more feasible."

Courtesy of Haas Automation

An operator tightens the clamp on a turning tool prior to loading it in a CNC lathe at Haas Automation.

Courtesy of Haas Automation

An operator changes a turning insert.

Ludeking admitted this strategy isn't for everyone. "Different manufacturers are going to draw the line at different places, but if it were my shop, I'd look at combining quick-change and redundant tooling with using a general-purpose grade whenever my setup time approaches 10 percent of the time spent in production. This offers a nice balance between setup time and production efficiency, and makes life simpler for the operator."

Don't Forget the Code

Whether you agree with that figure or not, you still need to consider the programming side of this equation. Most CNC lathes come equipped with tool presetters, so even the most deliberate of machinists should be able to touch off a new insert in less than a minute. The biggest piece of the setup-time pie is tweaking the feeds, speeds, DOCs and possibly the toolpaths when introducing a new carbide grade.

Whatever cutting strategy is chosen, CAM software must back it up. "There's no 'easy button' in ours or anyone else's software that says, 'Hey, I'm cutting Inconel but am using a carbide grade more suitable for 1018 steel; please change the program to compensate,' " said Ben Mund, corporate marketing manager for Mastercam developer CNC Software Inc., Tolland, Conn. "No, it's up to the CAM programmer to dial in the cutting conditions for any given machining situation."

Whether applying one grade to turn most everything or a dedicated grade for each material, a tool library with cutting parameters for each combination of material and insert should be developed. Once that's done, the rest is gravy. Mund said it's best to start with the toolmaker's recommendations and adjust from there. "Any good CAM system will allow you to input whatever information is needed to optimize the cutting tool for a given set of conditions."

In addition, CAM programs include turning strategies that can make a less-than-optimal carbide grade perform like, well … maybe not a superstar, but at least a second-string player. In Mastercam, for example, Incremental Roughing and Dynamic Motion toolpaths help to spread cutting loads across more of the insert, extending tool life. And, as its name implies, Tool Inspection allows for mid-cycle retraction of a turning tool to check for wear, a function that may prevent catastrophe when using an iffy carbide grade.

Everyone has an Opinion

Some might argue that insert optimization is like wandering a car lot looking for the perfect ride to the grocery store—unless your grocer is on the other side of the country, it's cheaper to just grab whatever's handy and go. Others are adamant that a tool precisely matched to the job is the fastest way to the finish line.

Wayne Reilly, director of machine shop operations at Haas Automation Inc., Oxnard, Calif., said sacrificing cutting performance in favor of changeover time only makes sense on short run jobs, yet at the same time conceded that the machine builder is working on grade and insert reduction in its own shop to reduce costs and eliminate stocking infrequently used inserts.

WGI Inc., an aerospace machine shop in Southwick, Mass., has tried to find a middle ground. As CNC Lathe Programmer Scott Gogal explained, the company machines a variety of materials, including high-temperature alloys, aluminum and mild steel. WGI has attempted to standardize its grades, but finds it's no simple task.

"We've always carried a range of different manufacturers' inserts," he said. "We use Kennametal and Sandvik Coromant for general turning applications, in addition to using Iscar for tough materials and Mitsubishi for a lot of the steel. I find that each manufacturer has its own niche, so we end up bouncing around a bit until we find the best insert for the job."

Despite the variety of cutting tools at WGI, Gogal said setup time isn't a problem. Each insert swap takes "a couple minutes," and program changes are minimal. Gogal tries to keep his tool library and post-processors up to date, but often finds it easier to manually adjust the machine code.

When it comes to toolcribs, WGI is probably the rule rather than the exception. Gogal is right: Each toolmaker has its own set of tricks up its sleeve, and smart shops take advantage of that if they want to stay competitive. Some day one of the scientists at Kennametal, Iscar or Bob's House of Carbide will invent a super tool, one that cuts every material equally well. Until that time, it pays to stay top of the latest insert technology, minimize changeover and regularly analyze insert strategy. It's not a one-size-fits-all world. CTE

Contributors

CNC Software Inc.

(800) 228-2877

www.mastercam.com

EXSYS Tool Inc.

(800) 397-9748

www.exsys-tool.com

Hass Automation Inc.

(800) 331-6746

www.haascnc.com

Mitsubishi Materials U.S.A. Corp.

(800) 523-0800

www.mmus.com

Walter USA LLC

(800) 945-5554

www.walter-tools.com/us

WGI Inc.

(413) 569-9444

www.wgi.us