Shop Operations: Odds and ends

Shop Operations: Odds and ends

James Harvey, Cutting Tool Engineering's Shop Operations columnist, offers some miscellaneous tips and and unusual methods of machining that worked for him—and may help other metalworkers.

When working in a shop, a time will come when you'll be obliged to attempt a technique or cutting routine you've never tried before. Those times can be a little unnerving. Most customers and employers want positive results immediately, which does not leave much room for error.

Following are some tips and unusual methods of machining that worked for me—and may help you.

- Use silicone mold release on toolholders for easier tool changes. Some tool changes can be bone jarring, especially when a toolholder has been in the spindle for long time. You should never leave a toolholder in the spindle for an extended length of time—even overnight.

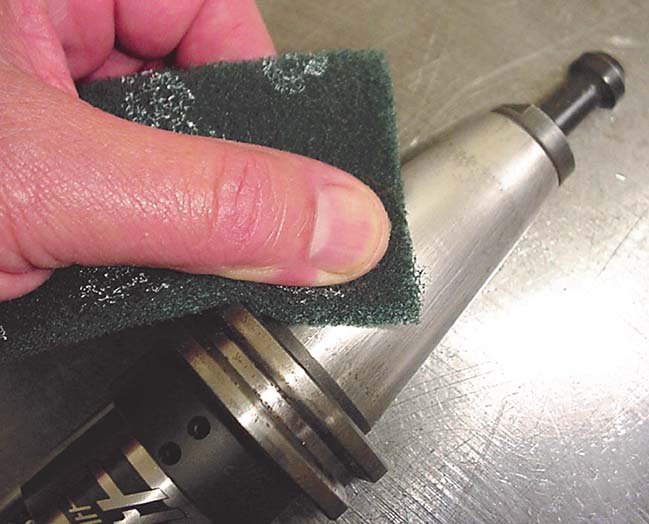

- Use a scouring pad to remove rust and gunk from a toolholder. The task of maintaining proper water-and-oil-coolant ratios in machines often gets overlooked. Typically, water just gets poured into machines when coolant levels get too low. Among other things, this practice can lead to rusty tapers on toolholders.

Use a kitchen scouring pad to remove rust from a toolholder. Image courtesy of J. Harvey.

- Producing parts via 3D printing can save time. Often, designers are not completely sure of themselves when designing prototype parts. They'll order one part from a machine shop and, if it works, they'll order more. This method is inefficient from a shop's perspective because shop personnel must find a suitable material, come up with the proper cutters, correctly program the job, effectively set up the machine and run a good part. If the part doesn't work, the process starts over. I've found that 3D printers are easy to use. Besides the printer, all that's needed is a CAD model and the powder material. Once you have a CAD model, all you have to do is print the part, possibly tap some holes and hand it to the designer. If all is well, the designer will order machined parts only once.

- Burrs are a fact of life in machining. Any cutting tool will throw a burr; sharp tools less so. Burrs must be removed from machined parts by hook or crook (often by a file). If you rerun the initial facing tool over the part after you have machined features such as holes and the perimeter of the part, you reduce the effort it takes to remove burrs simply because many of them get cut off during this final pass.

- Cut hard materials with carbide cutting tools, don't apply coolant (just air, if available), run tools at slow spindle speeds and take DOCs from 0.002" to 0.003". After parts get hardened via heat treating, they often need rework for various reasons.

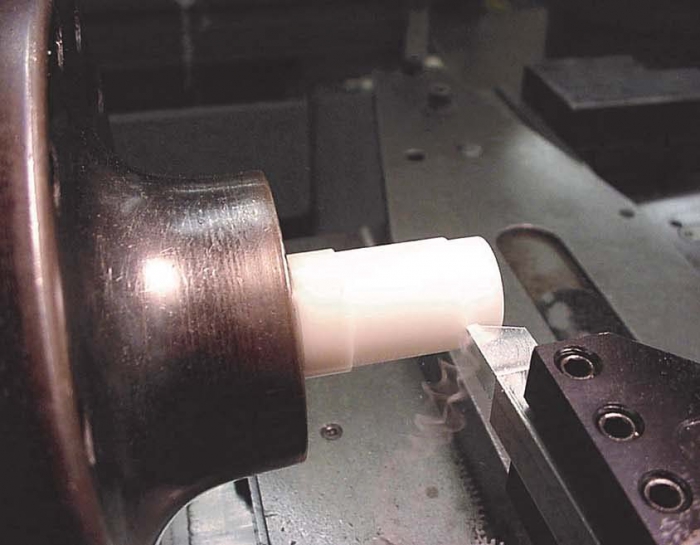

An aluminum tool machines a Delrin part. Image courtesy of J. Harvey.

- Cutting tools must be harder than the material they machine. This sound obvious within the realm of machining. To experiment, I took this concept a step further. I ground a piece of 7075-T6 aluminum into the shape of a lathe tool and proceeded to cut a Delrin part. Delrin is a rigid plastic, which is relatively stable and easy to machine. The aluminum tool held up well and imparted a fine surface finish.

- Use negative-rake endmills to push flimsy parts down onto your parallels and holding fixtures. The cutting force of negative-rake endmills tends to push the material being cut toward the bottom of the endmill. You can use this force to your advantage when machining parts that are not held too securely. The force tends to push parts against parallels instead of pulling them off, as would be the case when applying positive-rake endmills. The rake angle of a cutter is the angle that chips slide over.

- In a pinch, use a CNC machine to broach blind keyways, which are often cut with an EDM. The programming and setup can be tricky on a CNC machine because it's probably not something you often do. The spindle must be lined up and locked using an M code. First, rough out as much of the keyway as practical with an endmill. Then, find or make a sturdy broaching tool and program the tool to take light cuts (0.001") as it enters the roughed-out slot. Use cutting oil. I've found this method is faster than EDMing.

[Editor's note: This column is the final installment from "CNC Trade Secrets."]