Grinding Machines

Versatile 5-Axis Grinder

Star Cutter’s NXT 5-axis Tool Grinder is a versatile 5-axis CNC machine, features a small footprint and a large grind zone. The machine can run small and large diameter wheels and is designed in a modular fashion that offers quick adaptation to application requirements.

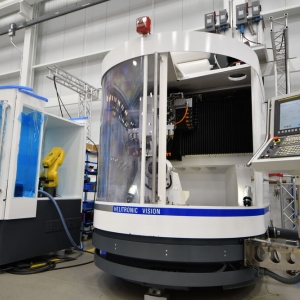

Grinding Meets Erosion!

Two technologies, one machine: The new VOLLMER VHybrid 360 combines the strengths of an innovative grinding machine and a proven powerful erosion machine. Allowing you to switch between the two functions in no time! Efficient processing and powerful machining of carbide tools with diameters of up to 50 mm.