Inserts

Contact Details

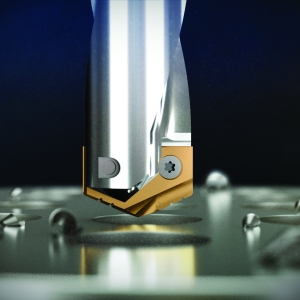

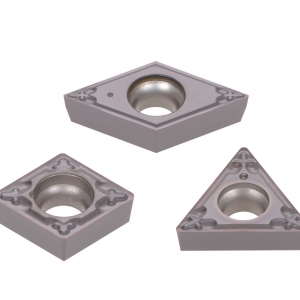

New DoForce-Tri 07 Insert Maximizes Shoulder Milling Productivity

Tungaloy expands its DoForce-Tri line of square shoulder milling cutters to include a size 07 insert, with 6 cutting edges for precision milling and insert economy. The DoForce-Tri 07 insert allows the insert density and feed capability to be as high as double that of the conventional, trigonal insert, while maintaining the same D.O.C. This is possible because of the innovative, curved cutting edge geometry on a smaller insert. The insert has 6 cutting edges that include a wiper. The tool also has high wall accuracy because of the optimized insert design.

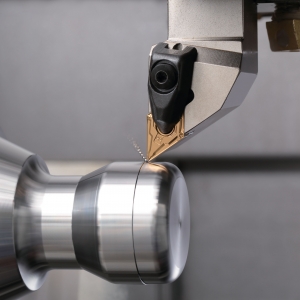

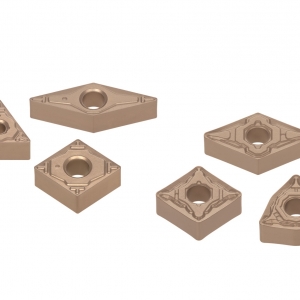

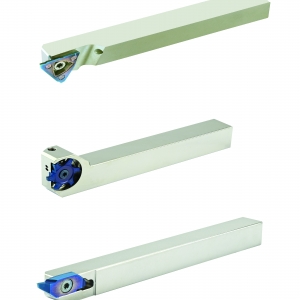

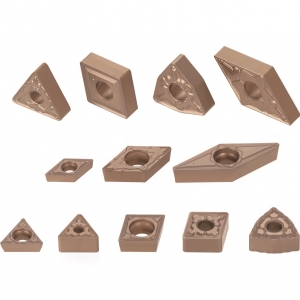

TurnTen-Feed | Efficiency and Economy in Medium-Heavy Turning

Components for the aerospace, power and heavy equipment sectors require high material removal rates and extended machining hours. These expensive components require high machining reliability and tool life predictability. TurnTen-Feed provides that tool reliability and machining efficiency in medium-heavy turning. The insert features 10 cost-efficient cutting edges. It’s double-sided and securely mounted with a dovetail clamping system, ensuring high reliability and stability.