Milling Machines

Contact Details

Tormach 1100M: Making a Mold for a Carbon Fiber Corvette Intake

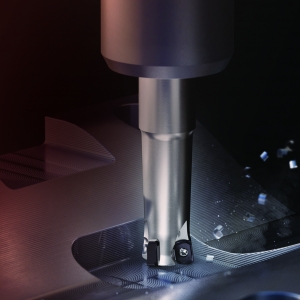

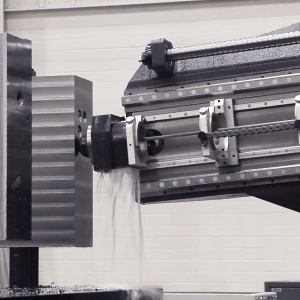

Are you looking for a dedicated prototyping CNC mill that allows you to keep your moneymakers running production? Want to keep your part making in-house to save time and money as you design/iterate? Check out the Tormach 1100M as it mills out an 87lb. aluminum block. This prototype mold was built to produce high-performance, after-market, carbon fiber intake manifolds for Corvettes. Your ability to dream is all that's holding you back!

For more information visit us at https://cnc.tormach.com/prototyping