Milling

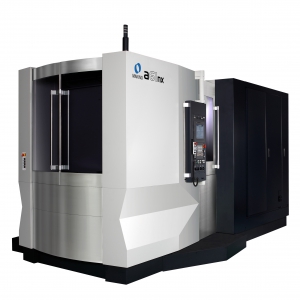

Matsuura LUMEX Avance-25 laser sintering, milling machine

The LUMEX Avance-25 laser sintering and milling machine integrates a fiber laser for state-of-the-art metal sintering and a machining center for performing high accuracy, high-speed milling, according to machine builder Matsuura Machinery Corp., Fukui City, Japan.

The LUMEX Avance-25 reportedly eliminates conventional processes, such as mold die splitting, electrical discharge processing, electrode designing, the fabrication of additional cooling water pipes, and assembly and adjustment work.