The abrasive stones commonly found in machine shops are fine for run-of-the-mill deburring and abrading. However, they are completely unsuitable for precision stoning. To perform proper precision stoning, you need a pair of carefully prepared, precision-ground flat stones.

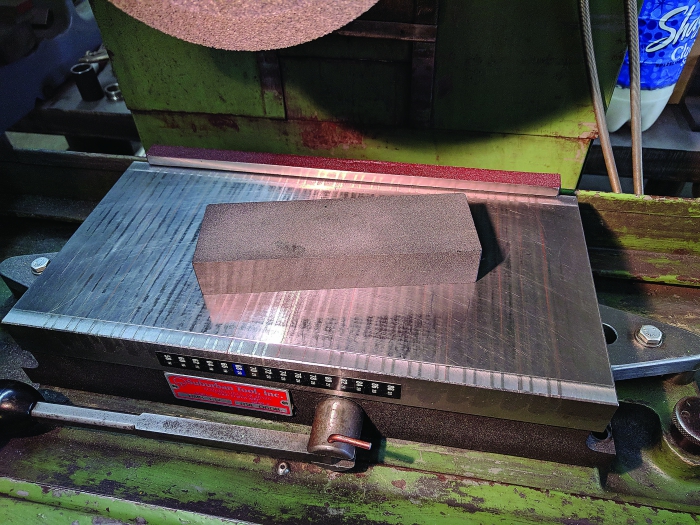

A common application for precision flat stones is stoning the part and the magnetic chuck of a surface grinder just prior to mounting the part (Figure 1). They are also used for removing small nicks and bruises from machine tool tables and accessories like parallels and vise jaws. In addition, flat stones can be carefully applied to detect and remove burrs and dings from male tapers, such as the ones on toolholders and spindles.

Figure 1. A common application for precision flat stones is stoning the magnetic chuck of a surface grinder just prior to mounting the part. Image courtesy of All images: T. Lipton.

Always used in pairs, flat stones have one or more of their large surfaces precision-ground flat and parallel on a surface grinder with a diamond wheel (Figure 2). Typically, one or more of the long perpendicular sides are also ground so the stones can deburr up to a shoulder. Some stones have a small step that allows stoning all the way to an edge or grinding relief. These truly precision tools have more in common with gage block stones than they do with abrasive stones, except flat stones cut more aggressively than gage block stones.

Common shop-grade aluminum-oxide stones are not particularly flat. I measured some new stones out of curiosity, and the typical flatness was 0.004" (0.10mm) to 0.006" (0.15mm). Flat stones are ground or lapped flat to less than 0.0001" (0.0025mm). This makes them suitable for use on highly accurate flat work. A more accurate description might be flat lapping stone.

Figure 2. Flat stones have one or more of their large surfaces precision-ground flat and parallel on a surface grinder with a diamond wheel.

Used like a ding-and-bump detector, flat stones do not remove base material, just material that protrudes above the workpiece surface. The porous structure of the abrasive allows tiny projections to be captured inside the pores and be sheared flush with the surface. Flat stones will not cut on a smooth surface but glide over it until they encounter projections—what I call “upstickers.” Flat stones are excellent diagnostic tools for finding surface anomalies.

To properly use flat stones, prepare the workpiece surface by first getting rid of large burrs or projections. Depending on their size and the workpiece material, you can apply a fine flat file or normal abrasive stone to knock down the main part of a large projection.

Figure 3. If a workpiece projection is correctly removed, a low spot surrounded by a polished ring in the shape of a ding appears.

Clean the workpiece thoroughly with a solvent that evaporates quickly and a clean wiper. Prior to applying the stones to the target surface, condition them by lightly rubbing one against its mate. This removes, or shears off, any embedded debris on the stones’ surfaces. The stones will glide together silently when they are clean and debris-free.

Next, gently slide one of the stones onto the work. Using just the weight of the stone, fish around for what I call “crunchies.” If you feel any loose debris rolling between the stone and work, stop immediately and reclean the workpiece surface. As you find small, raised areas or projections, the stone will bite—hence the name crunchies. You can begin to bear down with a little pressure to cut the bump and make that area flush with the main workpiece surface. Be sure to follow any machining or grinding lines already present in the workpiece.

If done correctly, you should be rewarded with a tiny pinprick of a low spot surrounded by a polished ring in the shape of the ding (Figure 3). This polished ring is flush with the surrounding surface to limits approaching 10µin. (0.0003mm).

Stones should be cleaned occasionally. Large embedded bits can be carefully picked out with a fine-point tool. Small holes in the stone are not a problem, but you don’t want any material projecting from its surface. An occasional quick spa treatment in an ultrasonic bath with a blow-dry treatment prolongs tool life.

At first glance, flat stones look nearly identical to common oilstones. Because flat stones cost many times that of common shop abrasive stones and files, it’s wise to protect your investment by storing them in a safe place so they aren’t used for roughing or common abrading tasks.

These stones are commercially available, such as from Professional Instruments Co., Hopkins, Minn., or you can make a set. I ground my first set of flat stones and then lapped them to final flatness on a diamond-impregnated lap.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- lapping

lapping

Finishing operation in which a loose, fine-grain abrasive in a liquid medium abrades material. Extremely accurate process that corrects minor shape imperfections, refines surface finishes and produces a close fit between mating surfaces.

- magnetic chuck

magnetic chuck

Workholding device used on surface grinders and milling machines for holding ferrous parts with large, flat sides. Holding power may be provided by permanent magnets or by an electromagnetic system. See chuck.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- relief

relief

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.