Innovative ‘fir tree cutter’ tool

Innovative ‘fir tree cutter’ tool

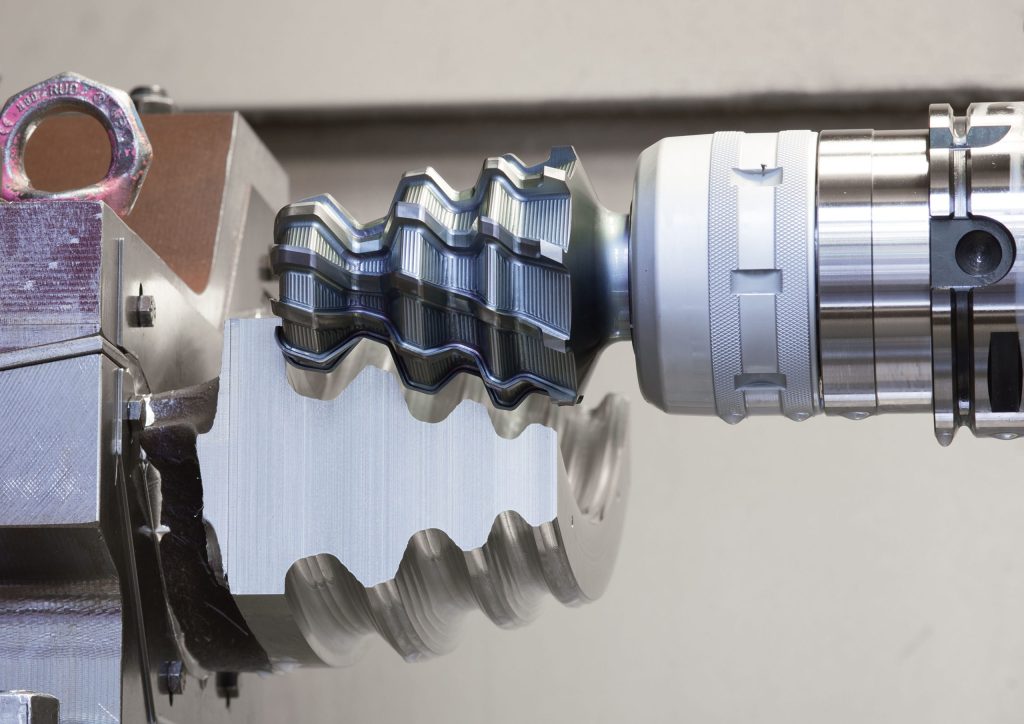

The tool's shape is a dead giveaway. The tooling, which resembles a Christmas tree, is often used for finishing blade root grooves and blade roots of turbines, is alternatively known as a fir-tree design, or a pine-tree, or now, a Pagode Tree Cutter developed by cutting tool solutions provider EMUGE-FRANKEN.

The tool's shape is a dead giveaway. The tooling, resembling a Christmas tree, is alternatively known as a fir-tree design, a pine-tree design, or, most recently, a Pagode Tree Cutter that was developed by cutting tool manufacturer EMUGE-FRANKEN.

The tool type is often used for finishing blade root slots and blade roots of turbines. Recently, EMUGE-FRANKEN USA, a leading manufacturer of high-performance end mills, taps, thread mills, drills, and other rotary cutting tools, teamed up with Okuma America Corporation to demonstrate EMUGE's Pagode tooling line and the multitasking machining innovations available for complex turbine components.

The unique cutting tool from EMUGE was installed on an Okuma MU-6300V Vertical Machining Center to simulate machining slots on the 550-millimeter turbine disk weighing, with fixture, 500 pounds, said Joseph Grigg, an Okuma application engineer who conducted the demo.

Pagode Cutter on Okuma MU8000VL">

Pagode Cutter on Okuma MU8000VL">EMUGE has redesigned and upgraded the traditional fir-design style cutter geometry. According to the company, the Pagode Tree Cutter features a new flute design, in which the fluting depth is consistent along the entire form, and it can be used in high-alloyed and highly heat-resistant materials. It is configurable in diameters from 40 to 200 mm and cutting lengths from 50 to 200 mm.

The "contour-adaption of the chip flutes," as EMUGE says of the tooling, allows for up to double the number of teeth, which results in an increased feed rate. The reduced space requires that the cutting edges be supplied with sufficient cooling.

To supply the cutting edges with sufficient coolant, the Pagode form cutter was designed with significantly more coolant exits.

"There are holes throughout the tool, going right through the center of the tool and then entering the gullet of the flute providing faster debris removal and increasing cutting speeds. It just blasts chips out," explained Grigg.

The tool features larger helix angles, and at least two cutting edges at in contact, simultaneously on the workpiece. This results in a smoother running tool and excellent surface finish quality on the part. The tangential relief grind of the cutting edges contributes to less wear and longer tool life.

The turbine disk demo at recent events featured a range of EMUGE tools: the Pagode tooling, skiving tools, TOP-Cut VAR end mill, MultiDRILL, chamfer mill, and an FPC tool holder. The demo featured Pagode rough and semi-rough tools for the rough slot and semi-finish root, but Grigg said the "star of the show" was the Pagode tool used for fine finishing the root.

"It's probably the most important piece of the puzzle because it's the one that gives us the beautiful finish," he said. "The profile is actually so smooth, and it is the Pagode tool that generates the excellent surface finish."

While the part and fixture came in at 500 pounds, it in no way came close to maxing out the machine. "We can load up to 1,300 pounds on this machine, and it has a max workpiece diameter of 830 millimeters," said Grigg. "We're only at 550 millimeters on this part, and we could go a hundred millimeters in both directions and 550 millimeters tall as well for larger parts."