Researchers improve machining, milling processes

Researchers improve machining, milling processes

Researchers at Missouri University of Science and Technology are helping manufacturers eliminate flaws introduced during the machining of large, costly components. In the February 2017 issue of the Journal of Manufacturing Science and Engineering, the Missouri S&T researchers describe their approach and explain how it can improve the accuracy of the 5-axis machine tools used to make large parts.

Researchers at Missouri University of Science and Technology are helping manufacturers eliminate flaws introduced during the machining of large, costly components. In the February 2017 issue of the Journal of Manufacturing Science and Engineering, the Missouri S&T researchers describe their approach and explain how it can improve the accuracy of the 5-axis machine tools used to make large parts.

According to Dr. Robert G. Landers, professor of mechanical and aerospace engineering and a co-author of the paper, "The way you want the machine to move is different than the way it actually moves due to inherent geometric errors." While several methods of compensating for these errors exist, none provides a complete solution, so manufacturers must combine various methods to get the best sense of a milling problem.

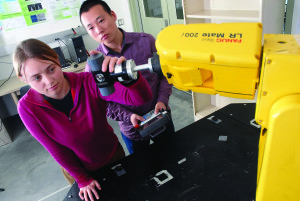

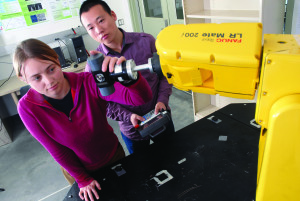

In her research, mechanical engineering doctoral student Jennifer Creamer, lead author of the paper, aimed to eliminate that piecemeal approach by capturing complicated geometric errors while automatically generating compensation tables for those errors.

The paper is also available in its entirety from ASME.

Ph.D. students Jennifer Creamer and Le Ma work in Precision Motion Control Laboratory.