Second rotary encoder for error-free workpiece transfer

Second rotary encoder for error-free workpiece transfer

Why does INDEX afford itself the luxury of installing a second rotary encoder on the Z-axis in its lathes for full-surface machining? The answer is safety and accuracy—two unbeatable arguments that customers treasure.

Why does INDEX afford itself the luxury of installing a second rotary encoder on the Z-axis in its lathes for full-surface machining? The answer is safety and accuracy—two unbeatable arguments that customers treasure.

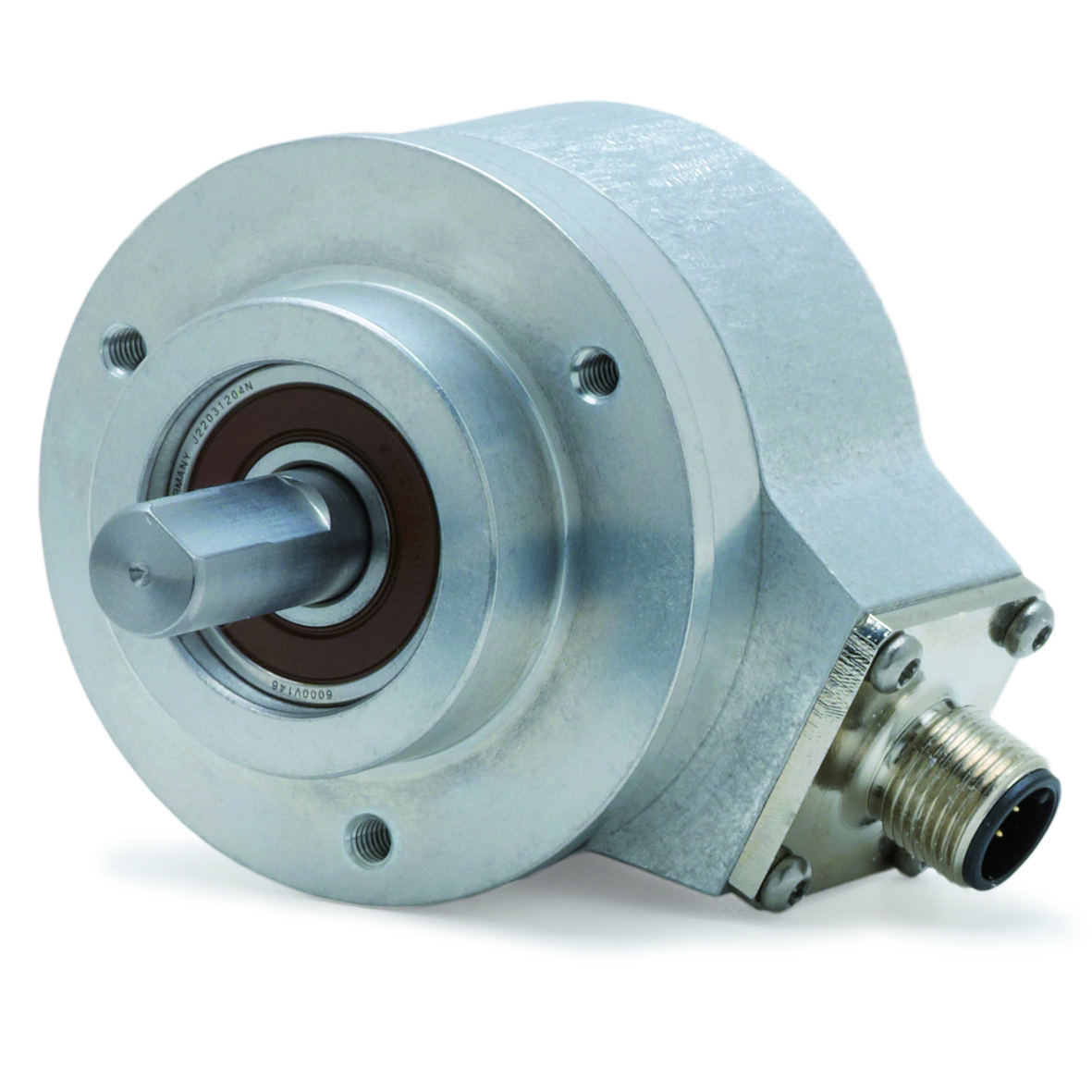

Multifunctional production centers for full-surface machining are the hallmarks of the INDEX Group, Esslingen am Neckar, Germany. The company's CNC lathes offer the user quality and accuracy on the one hand, and economical production costs on the other hand through short door-to-door times. One of the reasons for this is the precise transfer of workpieces from the main spindle to the counter spindle during six-sided full-surface machining. ROQ Model HEIDENHAIN rotary encoders with DRIVE-CLiQ interface play a decisive role here.

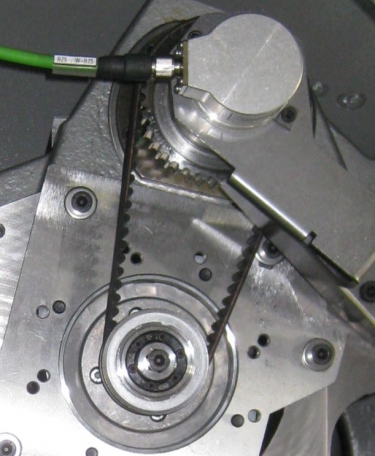

The ROQ model HEIDENHAIN rotary encoder sits directly on the Z-axis, which is driven by a motor through a toothed belt. Photos courtesy of INDEX-Werke

"The transfer of a workpiece in the lathe from the main spindle to the counter spindle is like handing over a baton in a relay in athletics: A tricky thing at which even professionals at world championships or in the Olympics repeatedly make mistakes. Highly complex processes are at play that we want to master on our machines," said Ulrich Baumann, manager of INDEX's single-spindle design department.

Now, no lathe operator has to worry about a workpiece falling out of the spindle like in a botched baton pass. Reliably transferring a workpiece from the main spindle to the counter spindle has long ago been solved. Here the devil is in the detail, or more precisely, in the accuracy of the transfer.

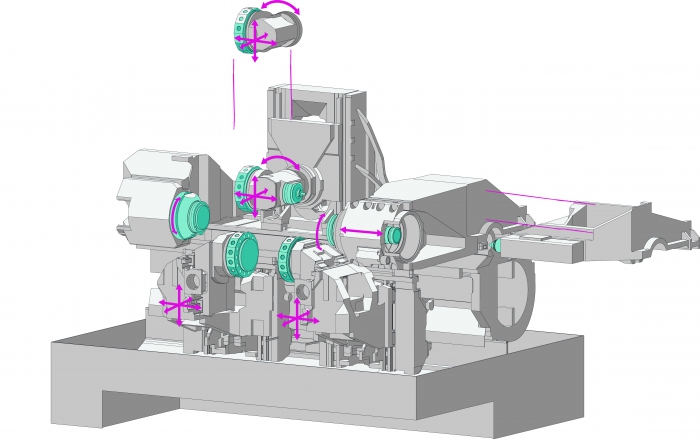

When the clamping elements are loosened and clamped on the main spindle and the counter spindle, it exerts forces on the workpiece and thus on the entire slide unit. This results in changes from the original workpiece position on the main spindle to the workpiece position on the counter spindle after transfer. "We have to measure these position changes so that we can compensate them again," Baumann added. "Otherwise, at the end of a six-sided, full-surface machining operation, the overall accuracy of the workpiece simply cannot be correct if dimensions have to be complied with beyond the first and second clamping."

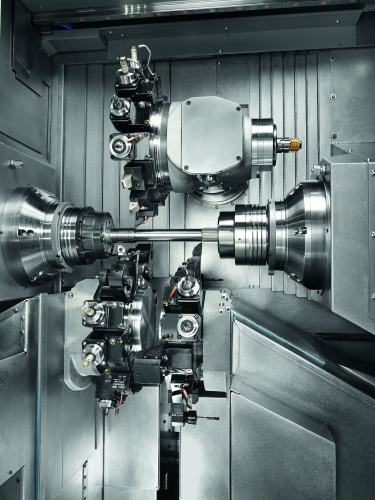

There's a lot happening in an INDEX G200; if you see the full working space, one can well imagine the consequences of a crash of the tool carriers with the opposing spindle.

Rules of thumb, experience, standard compensation values or a specified allowance cannot help here. Too many factors influence the displacement: Which clamping devices are used? What is the workpiece material? How are the surfaces of the chuck and workpiece? Does the workpiece have thick, stable walls or thin, sensitive walls? With what forces is the workpiece clamped in the main spindle on the unmachined side, and what forces can be exerted during the transfer from the counter spindle to the side that has already been machined? Even the cooling lubricant used has an influence on the position shift. "All these factors are machining-specific and highly individual. Friction, too, is always a factor—and friction is never constant. So we have to measure the influences in real time if we want to compensate them," Baumann said.

That's where the additional ROQ rotary encoder from HEIDENHAIN on the Z-axis helps. To transfer a workpiece from the main spindle to the counter spindle, the machine initially moves the counter spindle over the workpiece and the counter spindle then clamps it. During this clamping process, the axis moves due to the forces that are ascertained by the rotary encoder. The encoder then transmits the measured values to the control via its DRIVE-CLiQ interface, which offsets them during further machining.

"With the second rotary encoder on the Z-axis, we are closer to the cutting edge and can therefore measure more accurately than with the motor encoder. Thanks to this arrangement, we are able to reliably realize a length deviation of less than 0.02mm during the workpiece transfer process, " said Eberhard Beck, head of control technology at INDEX.

For six-sided full-surface machining to become possible, a lathe such as the INDEX G200 must coordinate highly complex motion sequences in all axes.

When searching for a suitable encoder for this application, the INDEX developers quickly came upon the ROQ encoder from HEIDENHAIN. "It is small, can be built in everywhere and is completely insensitive to contamination," as Beck explained the choice. Also, thanks to the DRIVE-CLiQ interface, it can be easily connected to the machine control and has sufficient reserves with a single-turn resolution of 24 bits to ensure the required accuracy.

Beck noted another argument for the additional encoder: the gain in safety. To save space, INDEX integrates the motor for the Z-axis backwards, so to speak, under the axis and drives it with a toothed belt. Depending on the amount of chips and the machine load, this toothed belt can tear and stop the spindle. The rotary encoder already on the motor would not detect such toothed belt failure. The machine would continue machining. "In the worst case, the tool carriers could crash into the stationary counter spindle," Beck pointed out: "Then up to 1 week of machine downtime and damage of several thousand euros are possible—a catastrophe for any company." Preventing such disasters is one of the HEIDENHAIN rotary encoder's tasks.