Industry News

07/26/2017

Florence, Ky.-based Mazak Corp. continues its advancement toward the complete digitization of all its manufacturing operations with the recent transformation of its Oguchi, Japan, facility into yet another Mazak iSmart Factory.

07/26/2017

Absolute Machine Tools Inc., Lorain, Ohio, has hired David Grega as COO. He will oversee the operation of Absolute's technical centers in Lorain and Mason, Ohio; Livonia, Mich.; and Elgin, Ill.

07/26/2017

Richmond, Ind.-based Osborn has picked Paul Dent to be its new director of sales for the Load Runners division.

07/25/2017

Irvine, Calif.-based CGTech, creator of Vericut, and MachiningCloud Inc., Camarillo, Calif., have announced a Vericut enhancement in MachiningCloud software whereby Vericut customers can import cutting parameters from cutting tool manufacturers from within MachiningCloud directly into Vericut.

07/25/2017

Driven by improving demand and steady global economic recovery, Taiwan's manufacturing output in terms of revenue is expected to grow 3.87 percent to NT$17.54 trillion (US$576 billion) this year, said the Industrial Technology Research Institute's Industrial Economics and Knowledge Center. Meanwhile, IEK said that in value-added terms, Taiwan's machine tool industry is the worst-performing segment behind all other segments of the manufacturing sector.

07/25/2017

President Donald Trump has issued an executive order on assessing and strengthening the manufacturing and defense industrial base and supply chain resiliency of the United States. He said strategic support for a vibrant domestic manufacturing sector, a vibrant defense industrial base and resilient supply chains is a significant national priority. A comprehensive evaluation of the defense industrial base and supply chains, with input from executive departments and agencies, has been ordered to assess the nation's strengths and weaknesses.

07/25/2017

Riverside Tool Corp., Elkhart, Ind., a Techniks Industries company, has acquired Cape Coral, Fla.-based General Saw Corp.

07/25/2017

The Valley Morning Star (Harlingen, TX) reports on how tool and die technology at Texas State Technical College has given student and former college dropout Andy Juarez "a new lease on life." Juarez plans to get his associate degree this Fall. "After speaking to supervisors at Arlington-based United States defense contractor and industrial corporation, Raytheon, he has a position waiting for him immediately after he graduates." The whole story is at the link.

07/25/2017

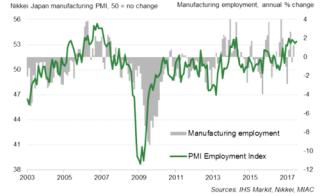

Japan’s manufacturing activity has fallen to an eight-month low in July, according to IHS Markit survey results. The Nikkei Flash Japan Manufacturing Purchasing Managers Index (PMI) for July is calculated to be a seasonally adjusted 52.2, following a 52.4 level in June. The Flash Manufacturing Output Index was pegged at at 51.4, down from 52.2 in June and the weakest growth in 10 months.

07/24/2017

Midwest Industrial Tool Grinding Inc., Hutchinson, Minn., has been named a finalist in the Workforce Development Award category for the Minnesota Business 2017 Manufacturing Awards.

07/21/2017

AGCO Corp., a worldwide manufacturer and distributor of agricultural equipment, announced ths week that it is increasing the efficiency, quality and safety of its manufacturing programs by doubling the number of Glass, an assisted reality, wearable headset device being used in its Jackson, Minnesota, factory, and will begin using Glass at six additional factories.

07/21/2017

Allied Machine & Engineering Corp., Dover, Ohio, a tooling manufacturer of complete holemaking solutions, has announced its new engineering training department, which provides comprehensive, hands-on education programs for new employees, end users and distributors from around the world.

07/21/2017

Lincolnshire, Ill.-based GF Machining Solutions LLC's System 3R, which supplies modular workholding/tooling systems, automation and software, is celebrating its 50-year anniversary.

07/21/2017

Seco Tools, LLC has partnered with Ferris State University (FSU) in Big Rapids, Michigan, to offer local area engineering students an opportunity to participate in a multi-year internship program at Seco. The program invites the top three engineering applicants to participate for an initial first year internship. Based on their interest and performance, the students may be asked back for a second year. Graduates of the program will often be offered employment by Seco.

07/20/2017

For today’s manufacturers of precision components, there’s no getting around deburring, rounding and polishing. These production steps are often seen as a necessary evil due to the high costs associated with them in some cases. Use of the right technology permits reliable processing at reduced costs.

07/19/2017

The 6 S system is a modified version of the lean manufacturing principle of 5 S. Developed by Taiichi Ohno, an industrial engineer for Toyota, lean production is a systemic method designed to optimize the efficiency of a business. Lean was born from the more specialized Toyota Production System, which is a system that helped Toyota grow from a small automobile manufacturer when it was founded in 1937 to where it is today: one of the largest manufacturing conglomerates in the world.

07/19/2017

"The clunky, AR device never really clicked with 'cool cache' in the public domain, but in the professional or industrial workplace Google Glass is turning out to be incredibly useful. Stripped of the Insta-photo, email-checking trimmings, the device is now being used to cleverly enhance workflows and make it easier for people to do their jobs."

07/19/2017

Stents and tubes are used in countless medical devices and new ones are being added every day, fueled in part by the growth of minimally invasive surgery and the commonplace use of stents. The sheer number and diversity of devices is rapidly increasing – and with it, the demand for more and more laser cut stents; flexible tubing, cannulas and micro cannulas, needles, biopsy devices and other minimally invasive tools.

07/19/2017

KOMET GROUP is using Renishaw metal additive-manufacturing technology to produce new ranges of innovative cutting tools. As well as allowing special cutters to be produced more quickly, the use of additive manufacturing enables more complex shapes to be generated, both for the external shape of the tooling and for the internal cooling channels.

07/18/2017

New commercial agreement between Spirit and Norsk Titanium identifies thousands of titanium parts currently manufactured at Spirit or by its suppliers as 3D-printing candidates.