Industry News

09/30/2022

For tiny precision components with dimensions of < 1 mm and deep-drawn from 100-micrometer thick sheet metal, the surface finishing operation can be quite a challenge.

09/29/2022

As shown at AMB this month, state-of-the-art grinding, measuring and coating technology used to grind precision tools with high accuracy requires that tool manufacturers be technically up to date and optimally coordinate all parameters involved.

09/28/2022

CNC Software hosts a Manufacturing Day event Oct. 7.

09/27/2022

As shown at IMTS this month, only through the use of extremely clean grinding oils can high-quality tools be ground economically and reliably against increasingly tight tolerance requirements.

09/26/2022

Purdue researchers use AM injector components from Velo3D to create Mach 6 conditions for a ground-testing facility.

09/23/2022

A breakthrough ultrahigh-precision robotic machine tool positions an object anywhere in a 215 mm circle with accuracy, speed and controlled force.

09/22/2022

To centralize operations and continue to better serve its customers, tooling supplier Ceratizit USA Inc. has shifted its official U.S. headquarters from Warren, Mich., to the company’s Schaumburg, Ill., facility.

09/21/2022

The award recognizes the world-class carbide manufacturing facility’s operational excellence, customer focus, and ongoing employee engagement.

09/20/2022

At the International Manufacturing Technology Show (IMTS) 2022, CGTech demonstrated its simulation software Vericut 9.3, which the company says boasts enhancements and new features to the core software to create smarter, more efficient manufacturing processes.

09/19/2022

A review is given of this machining method, its basic concepts and developments in the technology.

09/15/2022

Family-owned and -operated since 1968, Brannon Steel built a strong reputation as one of North America’s premier suppliers of carbon steel parts-to-print.

09/14/2022

Topics at Sandvik's technical training facility included breakthrough methods for turning and power skiving and tips to decrease cost per part, reduce setup and increase precision.

09/13/2022

Renishaw was a gold sponsor at a recent Haas tech center event.

09/12/2022

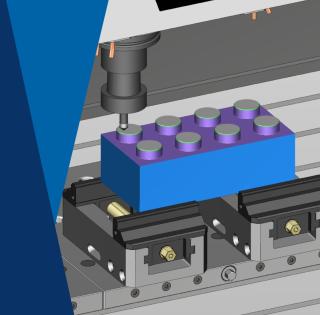

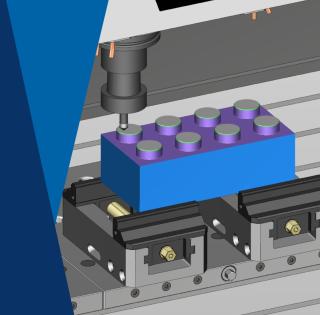

Andretti Autosport and a Big Daishowa engineer will demonstrate how UNILOCK workholding reduces setup times at IMTS.

09/09/2022

Eagerly awaited, IMTS is finally opening its doors again after a forced break due to the pandemic. And during the break, Mikron Tool’s R&D department has been busy developing better ways to machine demanding materials in the micron range. Some of them are "crazy."

09/08/2022

Armored vehicles need huge levels of drive torque to get going. To deliver the necessary propulsive force, manufacturers rely on transmissions from Augsburg-based Renk GmbH, the specialist in fully automatic transmissions for heavy-tracked military vehicles. And wherever top performance is required, you can be sure that solutions from WFL are not far behind.

09/07/2022

Moraine Park Technical College in West Bend, Wisconsin, and Siemens are working together to train workers in the manufacturing sector.

09/06/2022

Rush Machinery hires an electrical technician who is a graduate of the Finger Lakes Technical Center.

09/02/2022

Rush Machinery will showcase a balancing machine and a wheel truing and dressing machine at the 2022 International Manufacturing Technology Show (IMTS), being held at Chicago’s McCormick Place from September 12–17. Rush Machinery can be found in Booth 237233.

08/29/2022

Industrial automation is changing the way cutting tool manufacturers operate. Machines have taken on the heavy lifting at each stage of production, letting workers get on with less repetitive tasks.