Industry News

04/22/2022

The internationally operating MPS Micro Precision Systems AG (MPS) consistently uses grinding processes for demanding high-precision components in IT02 tolerance ranges. With a total of seven Studer grinding machines, the company has a cylindrical grinding expertise that is second-to-none.

04/22/2022

After Compact Flash and CFast, CFexpress marks the next most important leap forward in the development of industrial memory cards. Here are five arguments why this memory card is that step.

04/21/2022

There are numerous metal cutting technologies available to OEMs. For high-precision metal parts, photochemical etching might be the answer.

04/20/2022

The answer to manufacturing’s waste problem is hidden in data.

04/19/2022

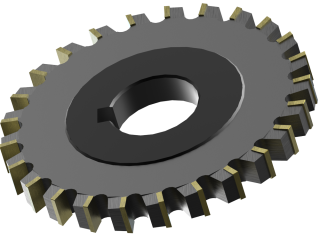

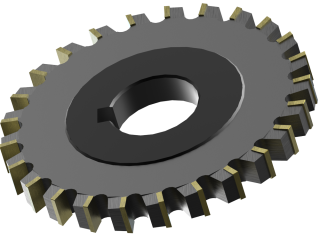

A technical guide on creating the perfect endmill.

04/18/2022

The operational stock of industrial robots hit a new record of about 3 million units worldwide – increasing by 13% on average each year (2015-2020).

04/14/2022

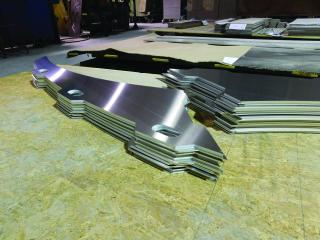

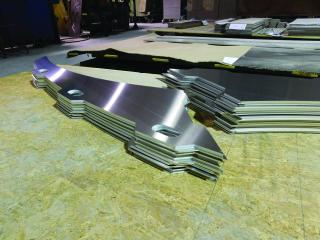

When manufacturing parts for critical aerospace applications, it is vital that the process chosen is not only cost-effective and allows adherence to time-to-market objectives, but is also able to adhere to tight tolerances and produces accurate parts at the right volume with minimal waste.

04/13/2022

Tindle Construction Inc. uses RADAN nesting and MRP essentials to efficiently process high volumes of sheet metal parts.

04/12/2022

PG Inspection Technologies has acquired the assets of Laser Measuring Technologies, manufacturer of the Accu-Tool and Accu-Edge inspection systems.

04/11/2022

ARCH Cutting Tools Corp. has acquired Greene Tool Systems, Inc., of Dayton, Ohio.

04/07/2022

GF Machining Solutions has established a Medical Center of Competency and has appointed a new medical business development manager, Donn Wuestenberg, to head its operations.

04/06/2022

Allied Machine and Engineering has launched an online digital platform, Allied’s Interactive Experience.

04/06/2022

Okuma and Morris Group opened a technical center and showroom in Elgin, Illinois.

04/05/2022

ANCA recently launched "The ANCA Academy," a series of videos that cover a different technical topic each month. The second video in the series is called "Machine Basics: Starting Up Your Machine Before Grinding."

04/04/2022

Eriez named Eric Nelson as vice president-international operations and business development.

03/30/2022

In many industries, new and enhanced products lead to high cleanliness specifications. Due to changed manufacturing, joining and coating technologies and more stringent regulatory specifications, there are stricter requirements for particulate and film-type part cleanliness.

03/29/2022

Standard parts and components are as vital to engineering today as they were in the mid-twentieth century. The main changes in the industry have been the technology that has enabled faster design and manufacture, enabling greater productivity.

03/28/2022

New technology has enabled F.O. Select to easily achieve greater quality, efficiency and durability of cutting tools.

03/25/2022

H.B. Carbide, a manufacturer and global supplier of carbide blanks and pre-forms, launched a website full of interactive tools that help guide customers in their carbide blank and pre-form purchasing decisions.

03/24/2022

Precision Drive Systems (PDS), a global provider of precision motor spindles, expert support, and repair near Charlotte, NC, announced Doug Lawrence as its product manager and subject matter expert (SME) for its metalworking spindle repair business.