Industry News

02/28/2022

In an email to Cutting Tool Engineering, Kaylee Dudek, a full-time employee in the application engineering department at Allied Machine & Engineering, Dover, Ohio, describes the impact of winning a $5,000 scholarship from the U.S. Cutting Tool Institute.

02/28/2022

WLR Precision Engineering is a contract machining specialist in Wilford, Nottinghamshire, and the company was using a pair of 15-year-old coordinate measuring machines (CMMs) in its inspection room. Looking to upgrade the technology, WLR Precision invested in two CMMs manufactured by LK Metrology. Soon, they had largely superseded the older CMMs.

02/28/2022

The Basics of Static Electricity white paper presents 20 comprehensive and full-colored pages on the causes of static electricity, how it develops, and solutions for combatting it in manufacturing processes.

02/23/2022

The use of industrial robots in factories around the world is accelerating at a high rate: 126 robots per 10,000 employees is the new average of global robot density in the manufacturing industries.

02/23/2022

Winning a U.S. Cutting Tool Institute scholarship in 2021 "was huge," and not just financially, according to Autumn Ohl, an aerospace engineering major in her freshman year at Kent State University, Kent, Ohio. USCTI, a trade association for manufacturers of cutting tools for the metalworking industry, awards a $5,000 scholarship to one lucky winner who plans to attend or is already enrolled in a college or vocational school program relevant to the manufacturing industry. This year's winner will be announced during the USCTI Spring Meeting, which is set for April 30 to May 2 in White Sulphur Springs, West Virginia.

02/23/2022

As a precision sheet metal machining technology, photo-chemical etching achieves exacting tolerances, is highly repeatable, and, in many instances, is the only technology that can cost-effectively manufacture precision metal components with the accuracy necessary in demanding, and often safety-critical applications.

02/19/2022

Photo-chemical etching is a viable alternative to legacy metal fabrication technologies and is seen in many applications as the only technology that can achieve the repeatability, accuracy, and geometric complexity demanded by OEMs from across myriad industries.

02/19/2022

The right cleaning process ensures product quality and cost-effectiveness.

02/17/2022

“Before purchasing a Vicivision, we had to use a variety of different machines,” explained a representative for Didimo Zanetti, a leader in the production of gears, as he opens the doors of the workshop and details how quality control worked before investing in an optical measuring machine.

02/17/2022

Veterans provide important transferrable skills throughout the Mazak company.

02/16/2022

Saint-Gobain Abrasives, one of the world’s largest abrasives manufacturers and primary sponsor of the USA Luge Team, celebrated the 40th anniversary of its partnership with the luge team during the Olympic Games in Beijing.

02/15/2022

Laser interferometry is susceptible to vibration issues. New technology is solving that problem.

02/14/2022

Effective complete machining of DAF camshafts for commercial vehicles is based on the sophisticated interplay between high performance high-performance linear motors, ultra-precise in-process measuring systems and easily accessible components. The Dutch truck manufacturer is extending its camshaft machining operations by adding the modular concept on the new platform 6.

02/11/2022

CNC machine tool spindles are essential to any drilling, milling, boring, grinding, routing, cutting, or sawing process, and many manufacturers and machine shops rely on rebuilders to get production back online as quickly as possible when problems arise, and replacement is required. However, rebuilding a spindle is not always as simple as shipping off a problematic unit to have its parts replaced.

02/10/2022

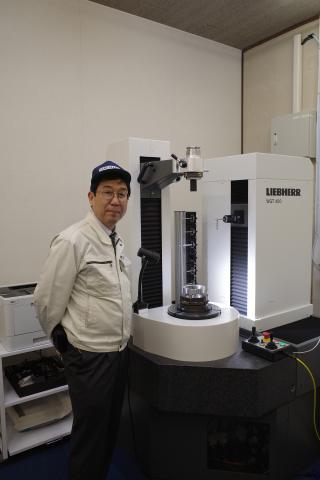

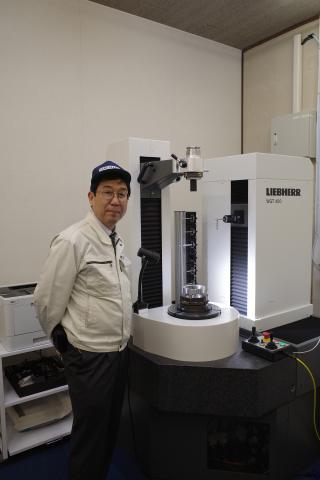

Seiwa Corp., the Japanese grinding machine maker, utilizes Liebherr measuring technology. Now Liebherr is offering Seiwa's grinding machines for its customers.

02/08/2022

Hetec GmbH, a machining technology specialist and supplier for tool, mold, and machine construction, has automated its production using the pallet handling system PHS 1500 Allround that helped tie together 5-axis machining centers into one high-production system.

02/07/2022

There has been a prevailing myth that manufacturers need to purchase brand new machine tools to incorporate flexible manufacturing systems (FMS). That is not true. Automating existing machine tools is possible and common.

02/07/2022

With its 5-axis CNC machines running 24 hours a day up to 7 days a week, Tech Manufacturing, a Pennsylvania-based supplier of machined metal parts for aerospace clients such as Boeing, Lockheed Martin, and Bombardier, looked to Moxa for smarter operation and real-time machine performance data.

02/07/2022

How robots help to qualify for the workplace of the future.

02/06/2022

To combat the loss of more seasoned operators to retirement, job shops are turning to more modern, automated surface grinders.