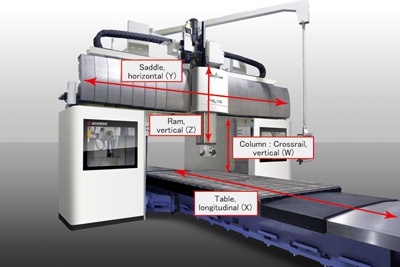

Mitsubishi Heavy Industries Ltd. (MHI) has completed development of and introduced the "MVR-Ex," a new model in the MVR Series of double-column 5-face milling machines that is one of MHI's leading large-size machine tool product lines. The new model incorporates the same main spindle internal cooling technology used ultra-high-precision machine tools, and reportedly is the first double-column machine tool in Japan to feature thermostabilized columns as standard equipment. Thermostabilization ensures superior machining precision by suppressing column deformation caused by fluctuations in the ambient temperature.

The MVR-Ex features a high-speed main spindle capable of 8,000 rotations per minute (min-1) as standard equipment. Main spindle expansion and bearing heating are suppressed by an internal cooling mechanism incorporated into the main spindle and ram, enhancing heavy-duty machining capability during both low-speed machining and high-speed, high-precision finishing of molds and other workpieces. In addition, thermostabilized columns enable factors such as column tilt and contraction (which cannot be addressed by conventional compensation mechanisms) to be suppressed to within 6µm per 500mm on both the X and Y axes. The MVR-Ex is also less affected by environmental changes at the installation site, and features a more rigid saddle and cross rails to enable high-power, stable cutting even when the ram is extended to 800mm.

A 15-inch control panel screen, roughly twice the size of earlier offerings, has been adopted for enhanced display of necessary information. Other operator-friendly features include improved maintenance screens and simple centering during workpiece setup, as well as a remote monitoring maintenance service function to enable the machine's operating status to be remotely monitored by MHI's service center for swift servicing response in the event of malfunction detection. The latest NC programs are also supported, along with an array of attachments that includes a right-angle head for machining lateral faces without a setup change.

For environmental compatibility the MVR-Ex is equipped with features such as a power regenerative function for the main spindle and servo motor, and LED lighting. These and other energy-saving features result in a reduction in CO2 emissions of approximately five tons per year in comparison to previous models.

Contact Details

Related Glossary Terms

- centering

centering

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.