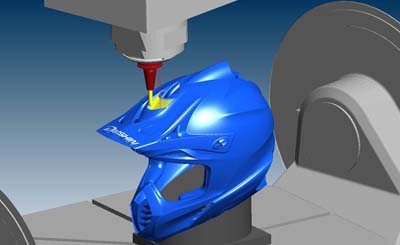

To apply hyperMILL's toolpaths reliably to the machine while avoiding any disruption during use, OPEN MIND Technologies AG produces all of its postprocessors itself for its customers. These postprocessors are therefore an integral component of a high-quality CAM postprocessor solution that goes far beyond generalised standard solutions in terms of performance and safety.

Development in the machine tool sector is proceeding rapidly. In the meantime, several milling machines can also perform turning operations, and the milling capabilities of turning machines are being enhanced every year. Complete machining of workpieces is commonplace among users turning, drilling and milling 2.5D, 3D, 5axis.

OPEN MIND Technologies AG has accompanied this development in the machine sector from the beginning, so they understand how the postprocessor, as the interface to tool machines, is an integral component of their high-quality CAM package. OPEN MIND produces nearly 100 percent of all of their postprocessors for this very reason. This successfully combines two crucial points in this service: specific customer requirements and performance, including the absolutely necessary factor of safety! Every user has specific ideas about the NC programming format based on their respective company's parts portfolio and their experience.

OPEN MIND strives to make these ideas a reality without losing sight of reliable performance. Several CAM producers simply give their customers a "generalised postprocessor." Users are then supposed to create their own postprocessors. This approach entails a number of disadvantages. For one, it costs the customer time. Second, the result is rarely one-hundred-percent optimal in terms of the combination of machine and controller, and machining potential cannot be fully exploited.

Finally, a user doesn't have the specialised expertise of postprocessor professionals. This comes with a certain level of risk. If there is a slight uncertainty factor in a complex 5axis program with multiple tools, this means that an additional NC verification is mandatory. This means that, after the postprocessor run, the NC program must once again be verified and edited. An additional loss of time. OPEN MIND's offer therefore goes far beyond the level of a generalised standard solution. The broadest spectrum of applications Postprocessors from OPEN MIND Technologies AG are outstanding thanks in part to the way they can optimally use the functionality of each controller.

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.