OPEN MIND Technologies AG introduces a new machining strategy in hyperMILL: 5AXIS Contour Offset Roughing and Finishing saves an enormous amount of time when creating CAM programs for parts with arched hub surfaces. Around 90 per cent of all CAM strategies are traditionally based on the assumption of two main orientations: the tool axis (Z axis) and the standard axis perpendicular to it. This is ideal for working in what is primarily a "flat" world.

Many parts, however, such as tyre moulds or engine casing parts, tend to be essentially arched, rather than flat. Previously they too could be machined by way of 5axis machines, but the CAM process consisted of multiple jobs or program steps. Consequently, the programmer was faced to program a large number of individual regions and needed to control boundaries and cutter orientation, which translated to a very high overall programming effort.

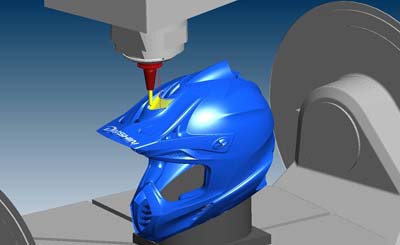

The new machining strategy in hyperMILL simply turns the arched surface into the standard surface, allowing the tool to work at any point at an angle of 90 degrees. Taking tyres as an example, one could say that the original plane is replaced by the tread. The strategy then works as if it involved "curved" Z roughing or finishing. The shape-offset techniques work in simple 4-axis cylindrical situations, but also with more complex 5-axis wrapped surfaces and any generalized shaped surfaces.

This allows the NC program to be created very easily and quickly. "With sample parts that I have processed with this strategy, I have seen programming time that was previously at two to three hours shrink down to just a few minutes. In one case five hours turned into a mere five minutes," explains Peter Brambs, Product Manager at OPEN MIND.

The new approach is ideally suited to the types of cavities frequently encountered in mould and tool engineering, as well as for the machining of turbine housings, structured parts (aerospace), tyre negative moulds and side panels, and furthermore synthetic wood models, roll dies, lenses, watch and jewellery components to name a few. Because the tool adjusts itself perpendicularly to the hub surface, there are hardly any undercuts. Each pocket, and each profile, can be machined very cleanly.

Any tool shape can be used: endmills, bullnose endmills, ball endmills and conical milling tools. The tool angle is calculated for machining either from the hub surfaces of the model or from an externally-designed guide surface. According to Peter Brambs, the machining results are "of extremely high quality." "The tool paths calculated on the basis of this strategy ensure optimal results, for example, in connection with rounded inner corners and automated approach and retract macros in finishing work. The part doesn't show any marks or steps."

Moreover, this strategy can be combined with hyperMAXX (machining strategy for high-performance roughing). This module, fully integrated with hyperMILL, combines optimal milling paths and maximum material removal and thus minimises machining times significantly.

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.