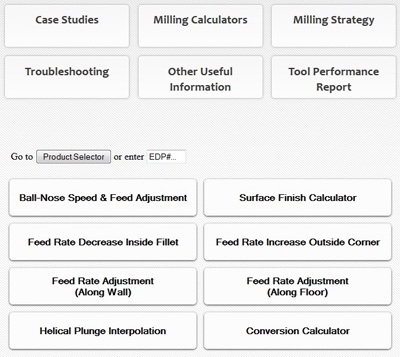

Helical Solutions LLC launched its new Product Selector and interactive Milling Calculators featured on www.1helical.com.

The new Product Selector feature allows users to quickly and easily locate the right endmill for the job by selecting from several options, according to the company.Users can search and choose from all of the company's products instantly and accurately. Once tools have been selected, the user can easily click the link to the new Milling Calculators, which provide instant technical support for many common milling operations.

The Helical Milling Calculators are improved, allowing users the option to select from program specific requirements and receive proven recommendations for each Helical tool selected. From chip thinning, feed through corners, feed rate adjustments, speed adjustments, conversion calculators and more, Helical Solutions can provide the right information to keep machines running efficiently.

Related Glossary Terms

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.