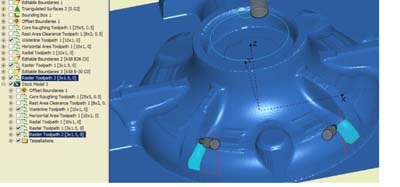

NCG CAM Solutions Ltd. UK's NCG CAM v12 includes a number of new features, including the ability to machine selected surfaces, the ability to generate ruled surfaces, thread milling, a tool size guide, core horizontal area passes, multi-axis stock models and a VERICUT tool list creator, as well as many enhancements.

A demonstration version of NCG CAM v12 is now available to download: http://www.ncgcam.com/demorequest.html.

In NCG CAM v12, the ability to machine selected surfaces has been added. This allows the user to select the individual surfaces to machine and then choose the machine selected surface; this will machine to the surfaces very edges, without the need to create a boundary first.

A new feature has been added which allows the user to generate a ruled surface from a set of curves, complementing the existing planar patch feature. In combination with the extract converted curves functionality in v11, the user can, for example, extend part surfaces so that machining carries on beyond their edges.

Users are now able to create a thread milling cycle. The canned cycles menu and dialog has been changed slightly.

A tool size guide has been added, allowing the user to define a circle or disc that represents the cutter diameter and which can be moved over the part with the cursor. The user is therefore now able to determine accessibility for a given cutter, without having to create the passes or do a lot of measuring.

Users can now machine horizontal areas by plunging off the job and then milling in from the side, using the new core horizontal area passes. In certain materials, such as Inconel (a nickel-chromium-based superalloy) and many other steels after heat treatment, machining in from the side will give far better tool life.

Stock models can now be created from multiple axis toolpaths, which will enable the user to visualise the stock resulting from a combination of 3, 3+2 and/or 5-axis toolpaths. The same stock model could also be used as a basisfor rest roughing after a number of machining operations with different tool axes, or against which other toolpaths can be edited.

A VERICUT tool list creator has been added to the NCG CAM post-processors, enabling VERICUT users to check NC tape files for collisions between machine parts and work piece when the tool axis is tilted. Setting the 'Vericut data' option in the post processor options that will create a tool list (*.tls) for the post processed operations. Once VERICUT is started that file can be loaded, defining the cutter and toolholder based on their NCG CAM definitions.

Contact Details

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.