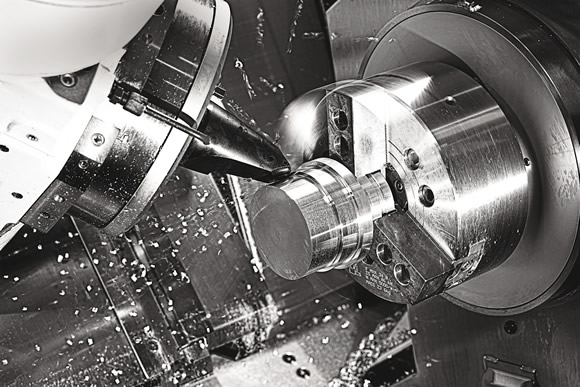

Courtesy of Okuma America

Turning a part with a Capto-equipped MULTUS B300II from Okuma. With up to 60-tools available in the magazine, 15-hp milling and B, Y and C axes, complex parts can be setup quickly and machined in one step.

While the basic CNC lathe is still a standby in many machine shops, new technology has vastly expanded turning capabilities. For example, live tooling and multiple turrets turn a basic lathe into a multitasking productivity center. When equipped with a large automatic toolchanger, these machines can hold tools for dozens of jobs, reduce setup time, and turn, mill, drill and finish parts in a single setup.

Dual-spindle turning centers can turn both ends of a part in a single setup to minimize operator handling, increase throughput and reduce work-in-process. The opposed spindles support synchronized turning and pass off parts on the fly, reducing overall cycle time. Such machines allow for the creation of more complex parts, and do so more efficiently. But questions like when are such machines needed, what kinds of parts can they produce and how do you justify the increased cost of a “supermachine” should all be taken into consideration before signing on the dotted line.

Can’t Touch This

Eliminating as many operations as possible is the most important consideration for shops looking at a new machine tool, according to Courtney Ortner, chief marketing officer for Lorain, Ohio-based Absolute Machine Tools Inc. “This is why multitasking machines can be so profitable,” she said. “Parts are often ‘done in one,’ eliminating work-in-process and improving quality.”

The Nexturn CNC Turning Center features a tooling layout that minimizes noncutting time while offering expanded part capability with a single setup.

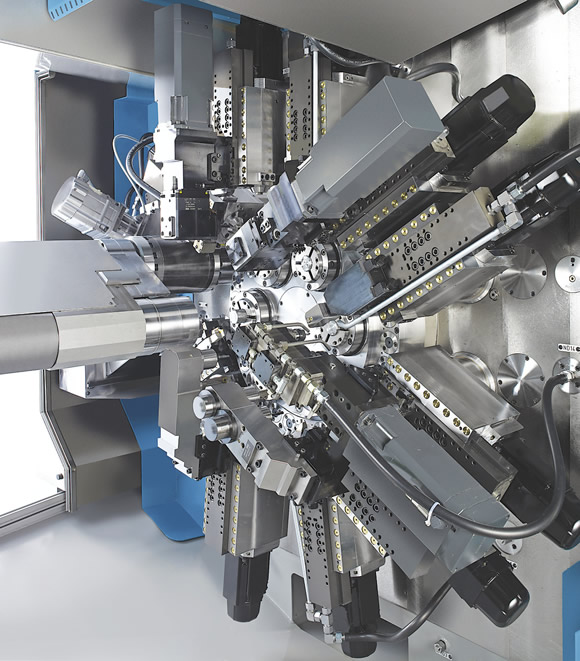

Courtesy of INDEX

The Index MS52C offers C-axis capability and 12 independent CNC slides, making it appropriate for high-volume, complex machining.

Ortner argued that turn/mill and other multitask machines reduce setup and fixturing costs while improving employee utilization compared to single-task machines. That’s because with multiple operations, operators do non-value-added tasks, such as part handling, which removes them from the equipment they are supposed to be monitoring and increases downtime. “An idle spindle is no different than going to the front door and throwing money into the wind,” she said. “Because more machining is done per cycle, multitask machines maintain a higher percentage of spindle uptime.”

Every shop owner knows the importance of keeping spindles turning, but it’s tough to justify spending half a million bucks or more on a turn/mill machine in the name of “saving money.” Many shop owners would argue that for the same price they can have a dedicated work cell. Their logic is sound—a team of plow horses is surely better for tilling a field than an expensive thoroughbred: If one of those old nags goes lame, the rest can carry the load, but if your high-priced racehorse breaks a leg, the field isn’t tilled.

David Fischer, product specialist for Okuma America Corp., Charlotte, N.C., cautioned that it’s not that simple, and end users must look at the overall picture. “Multitasking machines aren’t a cure-all, but neither is the attitude of ‘that’s the way we’ve always done it, so it must be right.’” Fischer agreed that users can certainly buy more spindles going the conventional route, but they must tool those machine tools and fixture them for each operation.

“I don’t care how many spindles you buy,” Fischer said. “What counts is how many parts you ship each day.” Consider a typical part with a couple of turning operations, some milling and maybe some drilling and tapping. Going the conventional route, after completing the first operation, the parts sit until the job running on the next machine is done. Multiplying this waiting game by the number of part operations equals a lot of unfinished parts.

WIP it Good

With a multitask machine, however, raw material is loaded and out comes a shippable product. Depending on the machine, machining time might be just as long as the sum of the “conventional” operations, but the primary goal of a multitask machine isn’t better cycle time—it’s to get the parts done in a single setup. And, because a multitask machine runs a complete part with every cycle, the time between part load/unload is longer.

As sales director for Hoffman Estates, Ill.-based DMG Mori Seiki USA Inc.’s turning division, it’s clear to Roberto Nicoli that parts manufacturers must implement more advanced technology. “Manufacturers must reduce the cost of manpower to stay competitive. By bringing multiple operations into a single piece of equipment, they can simplify the manufacturing process.”

Labor reduction or not, none of this brings would-be multitask machine owners any closer to the decision about which machine gets them to the productivity finish line. Choosing the right machine for complex parts requires disciplined decision-making. “Choosing any multitasking machine is complex,” Nicoli explained. “It requires teamwork between the customer, the dealer and the machine tool builder.”

Shop needs typically revolve around part complexity, size and quantity. Make a series of long, complex parts in high volumes and a Swiss-style machine might be in order. A variety of parts in small lot sizes typically calls for a twin-spindle machine with a toolchanger. High-volume jobs where cycle time is critical warrant multiple turrets to get more tools in the cut at the same time. And the complex, free-form surfaces seen in turbine blades and orthopedic components require B, C and Y axes, as well as a control and software that can drive complex toolpaths.

All this sounds great, but many shops struggle to set up and program “simple” 2-axis lathes. How does a machine with two spindles, three turrets, live tooling and a tool carousel hanging off the back simplify anything?

No More Headaches

Multitasking machines present more crash potential than a stock car race. Most are equipped with tool-life management software, quick-change tooling, collision avoidance and complex on-board programming routines, so new users may be faced with the mother of all learning curves.

Most machine tool builders offer a bewildering number of configurations. With multiple X, Y, Z, B, C and R axes, upper and lower turret options, live tools with toolchangers, pallet changers and the ability to grind, hob and broach in a single machine, the only limit is a shop’s credit line. Buy too little machine and you won’t produce parts any faster; buy too much and you’ve just wasted a lot of money for the jobs you already have.

Multitask machines take a lot more planning than commodity machines, not only during the purchasing process, but after installation. “Before you buy one of these machines, you need to look at your internal processes,” said Rich Parenteau, director of application development at Methods Machine Tools Inc., Sudbury, Mass. “You can spend a ton of money on your equipment, but if your guys are taking 15 minutes to find a ¼ " endmill, you’ll never get a dime back on that investment.”

This might be said for any machine tool, but when you have one that costs three to five times as much as a commodity machine, you want to squeeze it for all it’s worth. Parenteau advocates hiring dedicated organizers who focus on prep work.

“Multitasking machines offer upwards of 90 percent efficiency,” Parenteau said, “making it easy to justify one person to manage the internal process organization needed for a group of machines: Prep the tool wagon, preset the tools, ready the raw material. Everything is labeled and ready to go. All the operator has to do is change whatever tools aren’t resident in the machine, swap the jaws and hit cycle start.”

OK, but what about the program? Creating code for multiple operations and dozens of tools is daunting enough, but then you need to marry those toolpaths into an end-to-end process that takes full advantage of the multitask machine. Fortunately, machine tool suppliers are augmenting and, in some cases, replacing CAD/CAM systems with control-resident software capable of managing a multitask machine’s many moving parts.

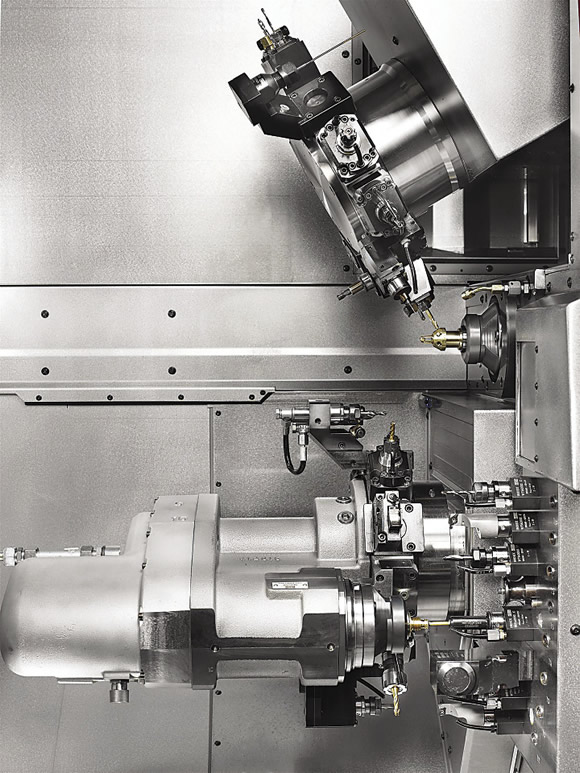

Courtesy of INDEX

The Traub TNL32 from INDEX can run in either fixed- or sliding-headstock mode. With 5-linear axes, 3-axis simultaneous machining and a large pool of fixed and driven tools, a variety of work is possible.

Methods’ CAMplete software is one example. “Whatever CAM system is used to generate the point-to-point code,” Parenteau pointed out, “it’s important to verify and optimize those toolpaths with a dedicated software package, such as CAMplete.”

That means analysis of the process using the actual tool library in a machine and exact 3-D machine models to eliminate any possibility of collision while applying as many tools as possible in the cut. It also saves endless hours of dry-running programs, he added. “The goal is to drop the program in and hit cycle start.”

Machine Quality

Perhaps the most important consideration when choosing a turn/mill or other multitask machine is quality. When making an investment of this magnitude and spending another 10 to 20 percent to tool it properly, a multitasking machine should run flawlessly. As Tyler Economan, proposal engineering manager for INDEX Corp., Noblesville, Ind., explained, no matter how good the cutting tools, workholder and CAD/CAM program are, you’re still marrying it all to an electromechanical platform.

“You want the ability to push the entire system to its limits,” he said. “That means a rigid design that can dampen vibration, compensate for thermal growth and provide accurate, precise motion control.”

These attributes are especially critical on a multitask machine, not only to assure part quality but also to make sure the many axes, spindles, motors and servodrives work together and do not break unexpectedly. “It’s about having a system that works—one that’s intuitive to operate, repeatable and dependable,” Economan said. “Even on complex machines like this, you should strive for a simple philosophy: Write the program, set the tools and let the machine make the parts.” CTE

Putting together the right toolbox

Cutting tools, toolholders and workholding are a big part of the equation for turn/mill and other multitask machines. According to Jason Farthing, technical sales and marketing at HORN USA Inc., Franklin, Tenn., the tooling that is selected must take into account the materials commonly used to make complex parts—nickel alloys, titanium and high-chromium alloys.

“We see a lot of shops moving in the multitasking direction, especially in the aerospace and medical markets,” he said. “One of the newer products available to address the difficult materials in this arena are carbide inserts that are both tough and hard. They can take a beating and resist wear at the same time. There are also several new coatings on the market that, when you get into tougher materials like Inconel or Hastelloy, offer high heat and abrasion resistance.”

Courtesy of HORN USA

HORN offers through-coolant tools that accept various grooving and cutoff inserts.

Now that you have high-quality cutting tools in your new multitask machine, how are you going to quickly change them? You can’t have quick changeover without investing in quick-change tooling, and with upwards of 100 tools in an ATC-enabled machine, that investment will be substantial.

David McHenry, senior technical engineer for Rego-Fix Tool Corp., Indianapolis, said his company is seeing a lot of the new machines with Capto-capable live spindles that utilize a C4 or C6 shank. The system is no longer proprietary to Sandvik Coromant, and other companies can make Capto systems, leading to additional tool choices.

Still, shop owners should expect a substantial investment in tools to make the most of their multitask machines. That includes turret tooling. It’s all well and good to have a Capto or HSK live spindle, but machine tool builders are reluctant to embrace just one quick-change tooling solution for their turrets, as no industry-wide mount exists offering interoperability between systems. As such, machines typically come with block tooling as standard. The good news is that shops have a variety of quick-change options. For roughly $1,000 per station, you can equip your shiny new multitask machine to swap cutting tools faster than Luke Skywalker can draw his lightsaber. The bad news: Many multitask machines have 50 or more tool stations, so you’d better plan on spending big bucks for a fully armed and operational Death Star.

Then comes the workholding. Buying a multitask machine with a standard hydraulic chuck is akin to putting snow tires on a racecar. When producing small lot sizes and a wide variety of parts, you need a faster and more flexible way to change-out and hold those parts.

Ron Wright, vice president of sales, toolholding and workholding for Schunk Inc., sees an increasing number of shops moving towards multitask and quick-change tooling—albeit at a high price tag. A workholding system from Morrisville, N.C.-based Schunk can cost $10,000, and most multitask machines have two spindles.

Wright easily justifies this: “Our solution actually reduces the workholding expenditure. Since you no longer have to build fixtures or top jaws for operations 20, 30, 40 and so on, you are spending far less. Add to that the ability to switch a set of jaws in under a minute or quickly install a collet chuck, face plate or air chuck, and you’ll frequently realize ROI in months.”

—K. Hanson

Contributors

Absolute Machine Tools Inc.

(800) 852-7825

www.absolutemachine.com

DMG Mori Seiki USA Inc.

(847) 593-5400

www.dmgmori-usa.com

HORN USA Inc.

(888) 818-HORN

www.hornusa.com

INDEX Corp.

(317) 770-6300

www.indextraub.com

Methods Machine Tools Inc.

(877) MMT-4CNC

www.methodsmachine.com

Okuma America Corp.

(704) 588-7000

www.okuma.com

Rego-Fix Tool Corp.

(317) 870-5959

www.rego-fix.com

Schunk Inc.

(919) 572-2705

www.schunk.com

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- automatic toolchanger

automatic toolchanger

Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restores the used tool to the magazine and selects and withdraws the next desired tool from the storage magazine. The changer is controlled by a set of prerecorded/predetermined instructions associated with the part(s) to be produced.

- broach

broach

Tapered tool, with a series of teeth of increasing length, that is pushed or pulled into a workpiece, successively removing small amounts of metal to enlarge a hole, slot or other opening to final size.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- cutoff

cutoff

Step that prepares a slug, blank or other workpiece for machining or other processing by separating it from the original stock. Performed on lathes, chucking machines, automatic screw machines and other turning machines. Also performed on milling machines, machining centers with slitting saws and sawing machines with cold (circular) saws, hacksaws, bandsaws or abrasive cutoff saws. See saw, sawing machine; turning.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- face plate

face plate

Flat, round workholder with slots used to hold regular- or irregular-shaped stock. If stock is markedly asymmetrical, counterbalances may be needed to prevent vibration.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- multifunction machines ( multitasking machines)

multifunction machines ( multitasking machines)

Machines and machining/turning centers capable of performing a variety of tasks, including milling, drilling, grinding boring, turning and cutoff, usually in just one setup.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.