Efficient removal of heat from the tool/workpiece interface is the main route to high-productivity machining. Several conventional methods are available to accomplish that—dry machining, minimum-quantity lubrication, flood coolant and high-pressure coolant—but cryogenic machining can be added to the list.

However, not all systems using cryogens take the same path to longer tool life and higher speeds and feeds. Presented here are three approaches, two of which use liquid nitrogen (LN2), while the other applies liquid CO2 mixed with air or an aerosol dry lubricant.

Watch for Flying Ice

At -321° F (-196° C), nitrogen is an effective, residue-free cryogen for combatting a cutting tool substrate’s worst enemy—heat. “If you don’t efficiently remove the heat, the result is thermal softening of the cutting tool and tool failure,” said Rana Ghosh, applications R&D manager for industrial gases at Air Products and Chemicals Inc. The Allentown, Pa., supplier of industrial gases developed the ICEFLY cryogen-delivery system and associated machining know-how to apply a cryogen at the cutting zone. The technology, which the company licenses, maintains a temperature from -250° F to 32° F (-157° to 0° C).

The system uses a proprietary coaxial, or tube-in-tube, geometry to flow high-pressure LN2 through the inner line and a low-pressure stream of LN2 through the outer line to minimize heat loss in the inner tube, Ghosh noted. The saturated, high-pressure LN2 stream is jetted through an external nozzle and immediately evaporates after impinging on the target surface, without leaving any residue.

According to 5ME, Lockheed Martin machined a medium-sized titanium (Ti6Al4V) aerospace structural component 52 percent faster with 5ME’s cryogenic machining technology than with coolant.

The ICEFLY cryogen-delivery system delivers nitrogen gas to cool the cutting edge.

One such nozzle, which can be retrofitted to virtually any vertical or horizontal machining center, is the Spidercool servodriven, programmable nozzle from Dimensional Control Inc., said Rick Knopf, owner of ICEFLY-licensee Industrial Cryogenic Technologies LLC, Macungie, Pa. The standard Spidercool, however, was redesigned with some new internal components to operate at such low temperatures without binding.

Ghosh noted ICEFLY is primarily targeted at five application areas: steel and iron harder than 45 HRC; sinter-hardened or heat-treated powdered metals; hard metal-matrix composites; cobalt chrome and other difficult materials for medical implants to avoid the use of traditional metalcutting fluids (long suspected as a source of contamination); and implants made of polymers, such as silicone, polyurethane and PEEK (polyether ether ketone).

When machining polymers, temperature control of the workpiece is key to prevent surface defects, such as cracking from overcooling and surface smearing and burr formation from undercooling, Knopf explained. Through optimal cooling of the uncut surface just prior to machining, the cryogen eliminates or greatly minimizes burr generation and enhances machinability. One example is a soft contact lens. “If you increase the modulus or stiffness of the workpiece surface, you can machine it,” he said. “Otherwise, you’re trying to machine a gummy bear.”

Unlike cutting metals, when machining polymers, the nitrogen stream is directed to the polymeric workpiece. To avoid overcooling and potentially introducing cracking when machined, Air Products developed a patented process that uses a mixture of liquid and gaseous nitrogen.

“We can dial in the optimal temperature of the fluid that needs to be jetted onto the material,” Ghosh noted, adding that the glass transition temperature of various polymers is a good starting point to establish cooling conditions with further optimization achieved through testing.

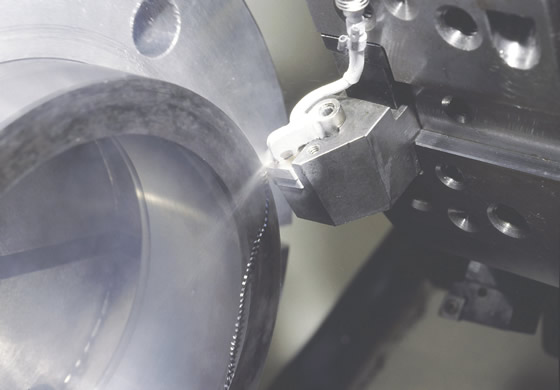

The cryogenic machining system from 5ME uses tube-in-tube, vacuum-jacketed feed lines to deliver LN2 from an external bulk storage tank to the cutting zone while protecting the integral machine components from being exposed to the low temperatures.

Applications expertise is a critical component of the cryomachining equation. For the majority of metalcutting, the focus is on cooling the tool and controlling the temperature and dimension of the workpiece, Ghosh explained. In situations involving workhardening materials or interrupted cutting, however, the focus is only on cooling the tool. For those cases, liquid nitrogen is injected from underneath the cutting tool. This enhances conductive cooling through the tool, while minimizing hardening of the unmachined work surfaces by overcooling.

According to Ghosh, cryogenic cooling can allow an end user to increase productivity 50 to 200 percent through a combination of higher cutting speeds and enabling the use of brittle cutting tool materials, such as alumina ceramics, in many applications where such tools cannot be used with flood coolant or when dry machining. However, greater gains are possible. In one wrought cobalt-chrome application, after switching from flood coolant and carbide tools to cryogenic machining and ceramic tools, the cutting speed went from 100 to 125 sfm (30.5 to 38.1 m/min.) to 550 to 700 sfm (167.6 to 213.4 m/min.).

Cryogenic machining also extends tool life, but manufacturing economics dictates that extended tool life shouldn’t be a primary goal. “Customers want to translate any tool life improvement into productivity gains because just having tool life improvement isn’t economical unless the tool material is PCBN or PCD,” Ghosh said.

Standard cutting tools are used, but Knopf pointed out that a major toolmaker purchased an ICEFLY system to conduct research on developing an insert grade specifically for cryogenic machining.

An Internal Approach

Liquid nitrogen can also be delivered through a machine tool spindle and a cutting tool directly to the cutting edge. This is the method Cincinnati-based 5ME LLC employs with its Cryo technology. The cryogenic machining system uses tube-in-tube, vacuum-jacketed feed lines to deliver LN2 from an external bulk storage tank, or dewar (vacuum flask), to the cutting zone while protecting the integral machine components from being exposed to the low temperatures, said Pete Tecos, executive vice president of marketing and product strategy.

Installation of the Cryo kit doesn’t involve removing the spindle. Instead, a lance, which also has the tube-in-tube, vacuum-jacketed design to keep the OD at ambient temperature, runs through the drawbar ID, noted Michael Judge, executive vice president of business development. “It’s very noninvasive.”

A vacuum-jacketed line, however, doesn’t run through a cutter body, so 5ME designed a line of indexable and solid-carbide cutting tools insulated with PTFE (polytetrafluoroethylene) to use with its cryogenic machining technology. “You cannot run the 5ME cryogenic machining technology system with non-5ME cryogenic tools,” Judge said. The company sells end users about 60 families of cutting tools, including endmills, facemills, high-feed mills, thread mills, drills and turning tools.

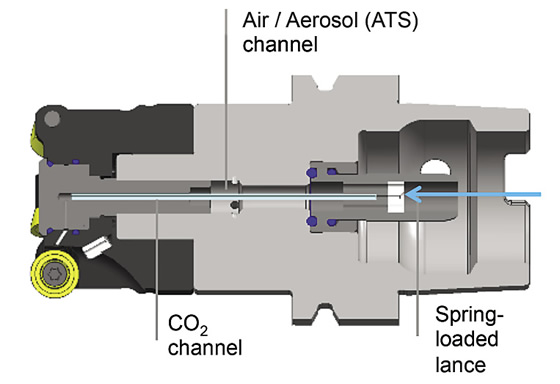

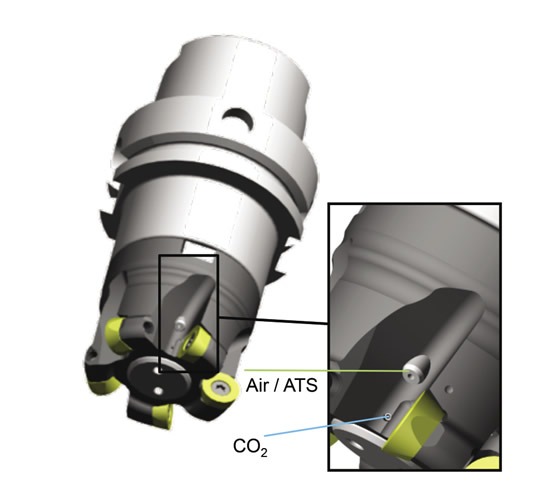

Cryo·tec tools from Walter have two cooling channels: one for CO2 and one for an aerosol dry lubricant or air. The tools have an optimized diameter and CO2 channel directions, as well as a tool shape designed to transport aerosol and air from the spindle through the tool body and to the insert.

Although 5ME is machine tool agnostic and willing to work with any builder, Judge noted the targeted machines are medium-sized horizontal machining centers and large vertical machining centers. This means an HMC with at least a 630mm (24.8 ") pallet size and a VMC with a large spindle, such as CAT 50, CAT 60 or HSK 100A. Targeting these machines helps ensure a reasonable payback because the Cryo hardware kit is about 30 percent of the cost for a new machine tool that size and larger.

“The return on investment for customers willing to share their data with us is from 8 to 14 months,” Judge said. “Our goal is to keep it within 18 months.”

Because the cryogen is vented away from the workpiece, the system prevents it from making the material more challenging to machine. An exception is when cutting composites, where allowing some liquid nitrogen to overflow avoids workpiece tearing or delamination, Judge said. “We did a 3-month testing plan with one of the larger commercial airline OEMs specific to drilling and trimming composites.”

To quantify the technology’s productivity when cutting metal, Judge noted an application at Lockheed Martin in which a medium-sized titanium (Ti6Al4V) aerospace structural component was machined 52 percent faster with 5ME’s cryogenic machining technology than with coolant (see photo on page 51). In addition to reducing cycle times, the LN2 process improves surface integrity and part quality by reducing residual stress, burr formation, grain boundary distortion and white, or martensitic, layer production during machining, according to company test results.

“All of those are just value-added benefits above and beyond being able to machine parts much faster and with less cost, as well as the green aspects for improved operator health and safety with the elimination of cutting fluids,” he said.

5ME continues to gain momentum with machine tool builders interested in Cryo, according to Judge, who expects development of “a significant number” of new projects in 2015. This perhaps is most clearly demonstrated by a strategic alliance signed between Okuma America Corp. and 5ME, according to Judge. In parallel, 5ME will integrate its cryogenic system onto one of the machines in Okuma’s new Aerospace Tech Center in Charlotte, N.C.

Nonetheless, the highest hurdle to market acceptance may be the end user’s mindset. ”We don’t have any direct competition with the intellectual property we have at 5ME,” he said. “It’s more about finding customers who have the right culture, are committed to change and looking for the next leapfrog technology to make parts faster and cleaner.”

Mix and Match

Liquid nitrogen isn’t the only cryogen in town. At -78.5° C (-109.3° F), liquid CO2 seems balmy compared to the frigidity of LN2, but it is effective at holding a cutting tool at ambient temperature to extend tool life and boost productivity while imparting finer finishes compared to noncryogenic approaches, according to Kevin Maples, RCC (regional competence center) Americas – aerospace and energy for Walter USA LLC, Waukesha, Wis.

Vikki Franke, project manager for cryogenic tooling in the R&D department at Walter AG, Tübingen, Germany, explained that CO2 is transported in a liquid phase at room temperature to the tool exit, where it expands into a gas and the low temperature occurs.

The manufacturer of precision tools developed Cryo·tec cutters for cryogenic machining (see diagrams on page 54). It teamed with the Starrag Group to demonstrate the CO2 cooling system in machine tools from the Switzerland-based builder, which offers retrofit services for its equipment. The retrofit includes exchanging the machine spindle.

“Technically, it’s not a problem to provide this technology for every existing Starrag machine on the market today,” said Michael Schedler, marketing manager for Starrag. (Starrag USA Inc. is located in Hebron, Ky.)

However, he noted Starrag is primarily targeting the system at one application: simultaneous 5-axis machining of blisks and blades, such as turbine blades, made of difficult-to-machine materials.

Unlike through-spindle, through-tool LN2 systems, the Starrag/Walter arrangement offers two channels: one for CO2 and one for air or an aerosol-based dry lubricant. This enables an end user to apply CO2-cooled aerosol, CO2 and air, just aerosol, just air or just CO2. When machining titanium, for example, Franke pointed out that some lubrication is needed to reduce friction.

She added that when air alone won’t do the trick, CO2 can be added, balancing the two for machining effectiveness and economy. “You try to use as little CO2 as necessary,” she said.

The tool bodies, which reportedly have an optimized diameter and cryogenic cooling channel, are specials, but accept standard indexable inserts, Franke noted.

While the tools are still being developed, Maples said one application saw a 44 percent productivity gain by switching from dry machining to CO2-cooled air, and the process can extend tool life by 50 to 70 percent.

Another significant indicator of cryogenic machining’s potential is the level of interest. “We’ve had discussions with a lot of customers and a lot of these projects sound very promising,” Schedler said. “I think it will have a big impact.” CTE

Contributors

Air Products and Chemicals Inc.

(866) 826-6035

www.airproducts.com

5ME LLC

(513) 719-1600

www.5me.com

Industrial Cryogenic Technologies LLC

(610) 966-8221

www.industrialcryotech.com

Starrag USA Inc.

(859) 534-5201

www.starrag.com

Walter USA LLC

(800) 945-5554

www.walter-tools.com/us

Related Glossary Terms

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- ceramics

ceramics

Cutting tool materials based on aluminum oxide and silicon nitride. Ceramic tools can withstand higher cutting speeds than cemented carbide tools when machining hardened steels, cast irons and high-temperature alloys.

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- cutting tool materials

cutting tool materials

Cutting tool materials include cemented carbides, ceramics, cermets, polycrystalline diamond, polycrystalline cubic boron nitride, some grades of tool steels and high-speed steels. See HSS, high-speed steels; PCBN, polycrystalline cubic boron nitride; PCD, polycrystalline diamond.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- hardening

hardening

Process of increasing the surface hardness of a part. It is accomplished by heating a piece of steel to a temperature within or above its critical range and then cooling (or quenching) it rapidly. In any heat-treatment operation, the rate of heating is important. Heat flows from the exterior to the interior of steel at a definite rate. If the steel is heated too quickly, the outside becomes hotter than the inside and the desired uniform structure cannot be obtained. If a piece is irregular in shape, a slow heating rate is essential to prevent warping and cracking. The heavier the section, the longer the heating time must be to achieve uniform results. Even after the correct temperature has been reached, the piece should be held at the temperature for a sufficient period of time to permit its thickest section to attain a uniform temperature. See workhardening.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- machinability

machinability

The relative ease of machining metals and alloys.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- minimum-quantity lubrication

minimum-quantity lubrication

Use of cutting fluids of only a minute amount—typically at a flow rate of 50 to 500 ml/hr.—which is about three to four orders of magnitude lower than the amount commonly used in flood cooling. The concept addresses the issues of environmental intrusiveness and occupational hazards associated with the airborne cutting fluid particles on factory shop floors. The minimization of cutting fluid also saves lubricant costs and the cleaning cycle time for workpieces, tooling and machines. Sometimes referred to as “near-dry lubrication” or “microlubrication.”

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- residual stress

residual stress

Stress present in a body that is free of external forces or thermal gradients.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- workhardening

workhardening

Tendency of all metals to become harder when they are machined or subjected to other stresses and strains. This trait is particularly pronounced in soft, low-carbon steel or alloys containing nickel and manganese—nonmagnetic stainless steel, high-manganese steel and the superalloys Inconel and Monel.