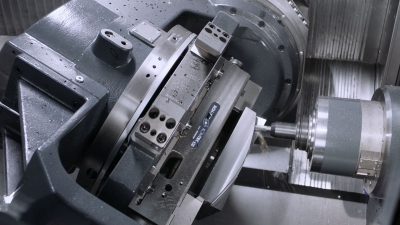

Heller Machine Tools introduces its versatile HF series 5-axis horizontal machining centers to North America for machining complex prismatic parts from lighter, smaller workpieces to heavier workpieces up to 800 kg table load. In the series of two machines, the fifth axis is provided by the workpiece on a swiveling trunnion with rotary table or a pallet changer for higher-volume production. Users can specify from a range of four spindle packages based on the material they are to process. Spindle speeds up to 18,000 rpm and torque up to 354 Nm are available.

According to the company, the main target groups of the HF series are the general machine industry and automotive suppliers. The two new machine models are Heller’s entry into a popular size range for these industries. The HF 5500 offers a work area of 900x950x900mm (X/Y/Z), and the smaller HF 3500 has a work envelope of 710/750/710mm (X/Y/Z).

With three linear axes in X, Y and Z and two rotary axes in A and B integrated into a rotary table on a trunnion, the HF machines are designed for five-sided machining and simultaneous 5-axis machining. The HF machines may alternatively be equipped with a lift-and-rotate pallet changer for series five-sided production. Standardized pallet automation solutions may be supplied by Fastems or Schuler.

Contrary to conventional 5-axis machining centers, Heller’s concept is not only based on single-part clamping but provides the possibility of multiple clamping or the clamping of very large components (transmission cases using ‘window-type’ fixtures).

The NC toolchanger is equipped with two NC axes for short idle times and consistent operation. The chain-type tool magazines capacities are: HSK63: 54, 80, 160 or HSK100: 50, 100,150.

As standard, Heller offers the SC63 SpeedCutting unit (18,000rpm, 100Nm) equipped with an HSK-A 63 spindle taper. Optionally available is the PC63 PowerCutting unit (12,000rpm, 201Nm), also equipped with an HSK-A 63 spindle taper, and the SC100 SpeedCutting unit (12,000rpm, 201Nm) as well as the PC100 PowerCutting unit (10,000rpm, 354Nm), both equipped with an HSK-A 100 spindle taper. The HF machines provide a rugged 8000 (HF3500) and 10,000Nm (HF5500) of feed force for handling even the most difficult materials without interruption or strain.

Recently, HELLER demonstrated the impressive capabilities of the HF series. Using a 100mm diameter facemilling cutter, a chip removal rate of 470cm3/min. was achieved, machining 1.2312 steel with a feed of ap = 3.5mm and an engagement width of ae = 75mm.

An optional Speed Package enables acceleration of up to 10m/s2 and rapid speeds of up to 90m/min. to be achieved on the HF series. This provides a reduction in chip-to-chip times of about 10 percent.

HF series machines are equipped with a Siemens control and a double pivoting main operator panel with a 24“ touchscreen as well as a newly developed Heller user interface for maximum ease of operation.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- facemilling

facemilling

Form of milling that produces a flat surface generally at right angles to the rotating axis of a cutter having teeth or inserts both on its periphery and on its end face.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

- work envelope

work envelope

Cube, sphere, cylinder or other physical space within which the cutting tool is capable of reaching.