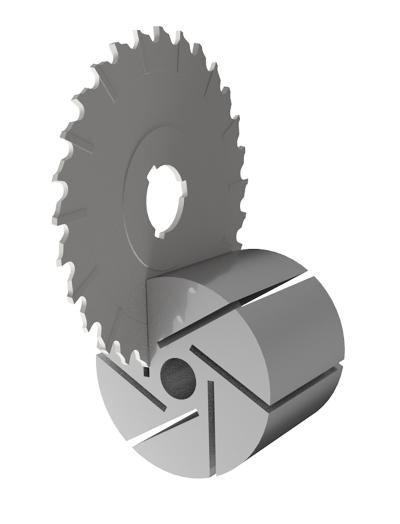

Controx milling cutters are suitable for the grooving of rotary vane and turbo pump rotors and other rotors requiring precision depth and width control. Slot widths of up to 5/8” and depths to 3” are possible with or without contour in the slot base.

Long service life is assured due to process-oriented choice of cutting material (special fine and ultrafine solid-carbide grades, HSS grades) and a selection of surface treatments (coating, edge preparation), according to the company. A special coating yields unmatched service life for aluminum. Adjusting the clamping surfaces and drive geometries to the toolholder provides safe and stable tool clamping.

Individual resharpenable tooth designs allow increased speed, which reduces the machining time and improve surface quality. A special side clearance design on the milling cutters for turbo pump rotors allows use on 5-axis machines.

Controx milling cutters are also available as balanced cutters. They are suitable for grooving the rotors of turbo pumps, grooving the rotors of rotary vane pumps and other precision grooving applications.

Contact Details

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.